FEATURE

* Model: TKB1600 S/E

* Payload: 12 Kg

* Arm Reach: 1412 mm

*DOF: 6 Axis

*Rated Power: 5.3 kw

*Body Weight: 48 kg

*Protective Specification: IP54

*Repeat Accuracy: ± 0.06mm

*Working Temperature: 0-45°

*Reducer Brand: China Laifu Harmonic reducer / Japan SHIMPO Harmonic reducer/

QinChuan RV reducer / Nabtesco RV reducer

*Drive Brand: NOVANCE Brand

CHARACTER

* Support Chinese/English/Japanese/Polish Spanish

* Programmable robot body, cables are made of special cables for flexible robots

* Support domestic and imported reducer mix, pure import, servo and reducer all import

* Support Chinese configurations or adopts imported reducer configurations of

NABTESCO, SHIMPO, etc

FEATURES

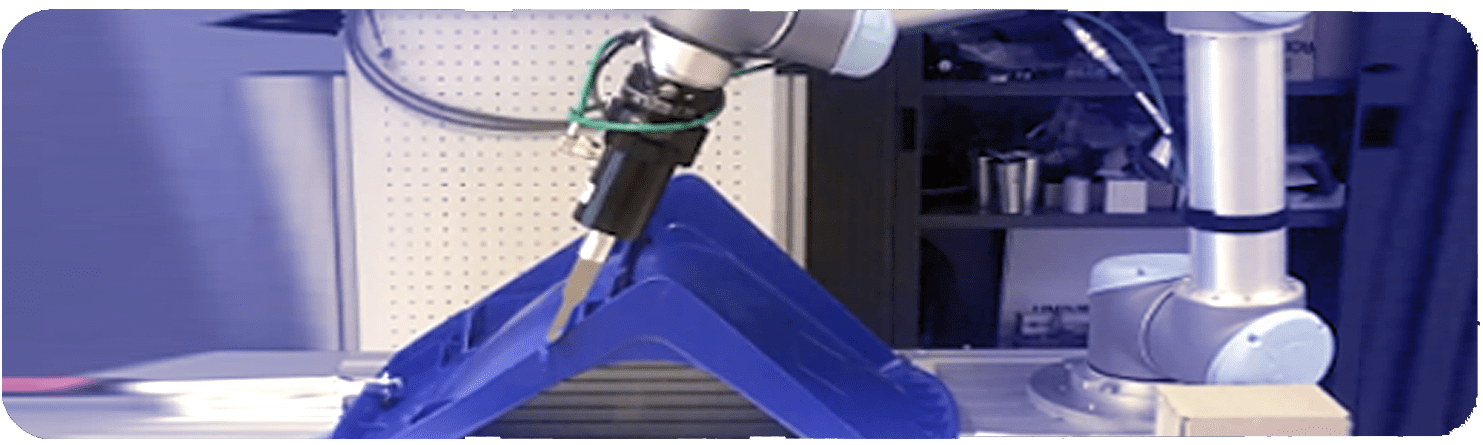

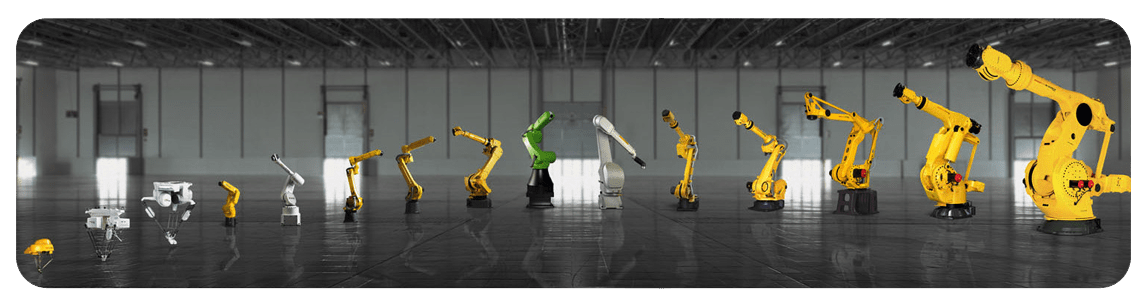

※ Industrial Robotic Arm TKB070 span is 910mm 7kg payload. It can be installed on the ground or upside down flexibly

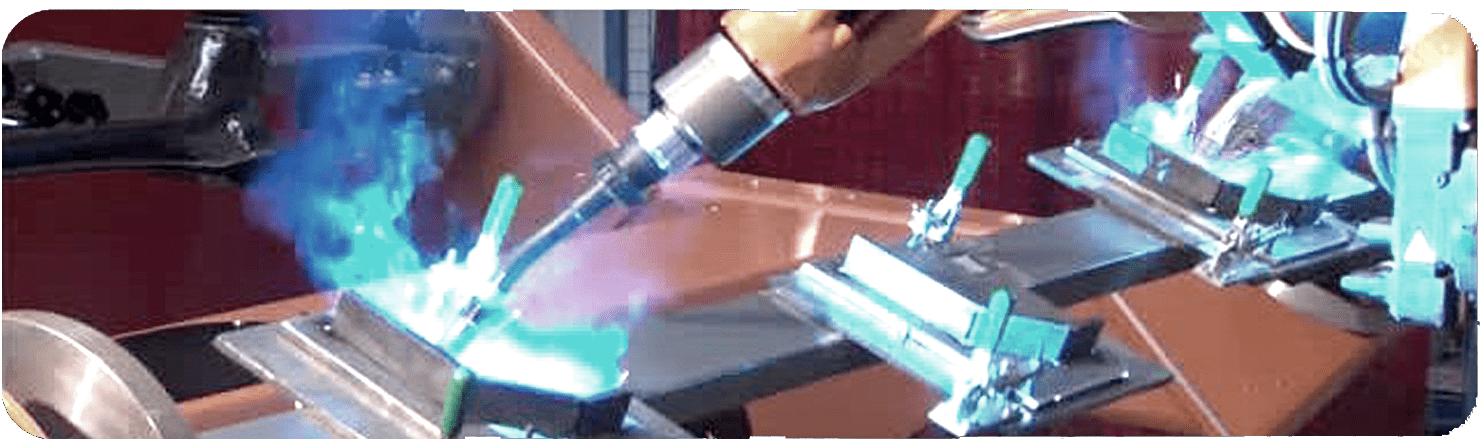

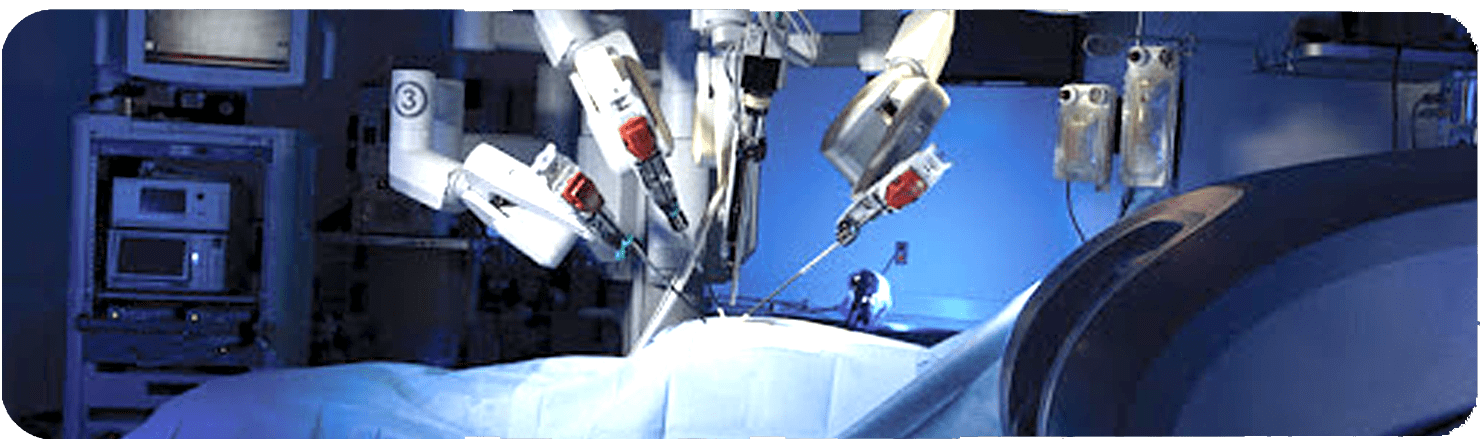

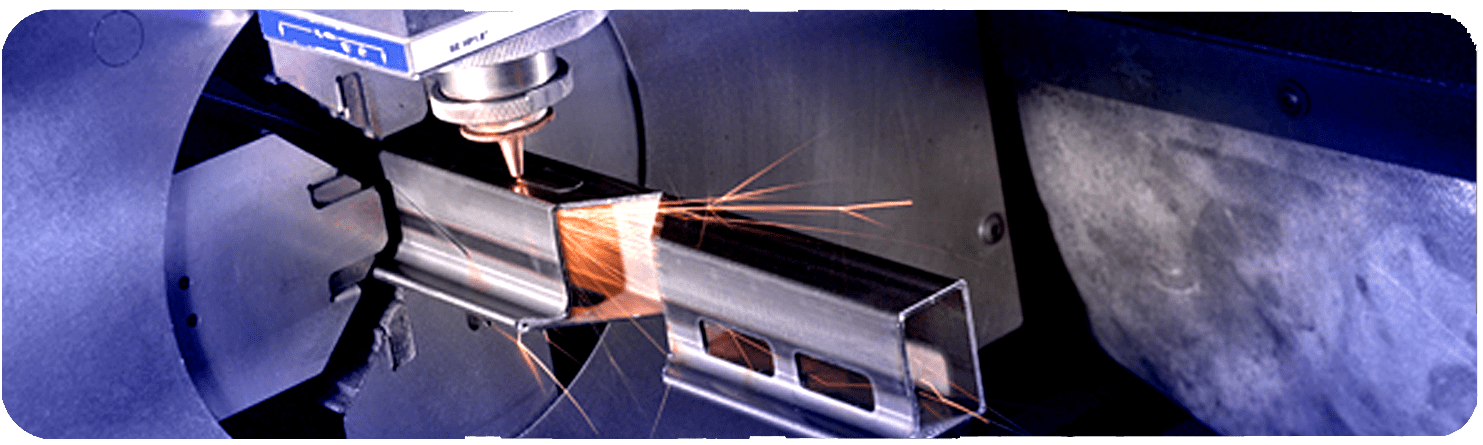

With large working space and fast running speed. our industrial robots are ideal for spraying, machine tool loading and unloading, handling, sorting, assembling and other pick and place applications

※Use Italian design technology in mechanical and circuit and take in ABB wiring layout technology in our robot body manufacturing. Use modular design to simplify wiring, double safety circuit design, and dust protection design for electricity cabinet

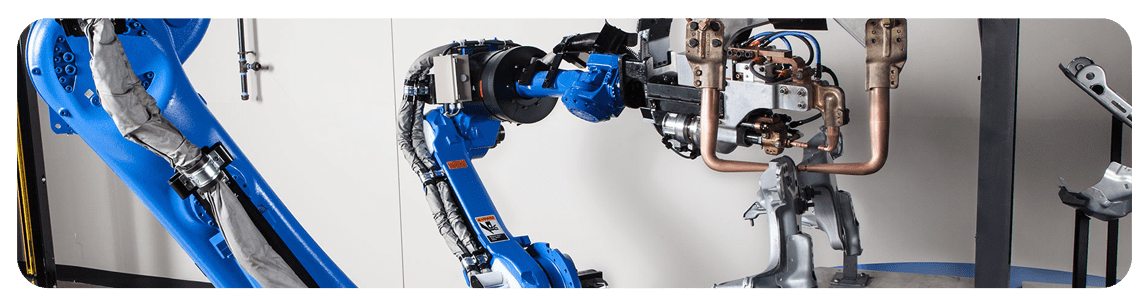

※Support Single phase, 220V working voltage can be better adapted in various environments. The robot body is with dual-circuit gas pipe and meets the welding and handling requirements

※ Programmable robot body, cables are made of special cables for flexible robots

※ The robot body is with dual-circuit gas pipe and meets the welding and handling requirements

※ 6+3 Axis (Standard 6 Axis, External 3 Axis is Optional)

※Support External PLC, Arc tracking and other accessories (optional), visual software (optional), laser tracking software (optional), arc tracking software (optional), etc.

※ Support Chinese/English/Japanese/Polish Spanish.

ROBOTIC ARM PROCEDURE

※ Bending: can realize constant speed tracking, real-time sensor tracking, bending

following and automatic return to equality function.

※ Spaying: four analog interfaces are provided, and standard trajectory template is built

in to generate spray trajectory quickly. At the same time, it supports users to build their

own spraying trajectory.

※ Palletizing: by setting the basic parameters of the size, number and number of layers

of palletizing, the palletizing and disassembling functions can be realized by simple

palletizing instructions.

※ Tracing: when the object moves on the conveyor belt, it can realize single tracking

(grabbing, spraying, etc.) or multiple tracking (assembling, etc.) of the product. It can set

tracking detection point, start point, end point and detection range arbitrarily.

※ Press tending: for press punching industry, a set of solutions for punching process,

punching interface and punching connection are developed, which are convenient for

customers to connect quickly, use simply and adjust the rhythm.

※ Pick and place

VISION & TRACKER

※Support third-party vision devices and protocols; such as Omron, Cognex, DALASA, etc.

※Three triggering modes of support instruction, timing and distance. Configuration List

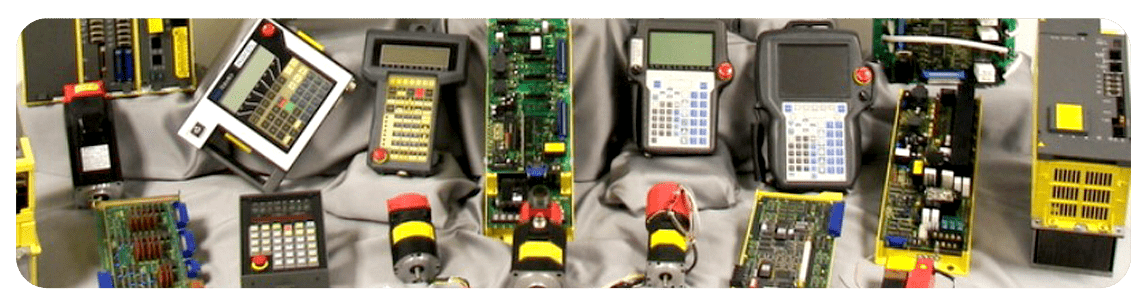

※Robot body.

※Electrical Cabinet (including controller, drives, IO board etc).

※Teaching pendant.

※Wiring cables 6 meters.

※Working process software.