Welcome to the machine vision department of Sorin Farbod Company.

OECD 2024 raporuna göre, Avrupa’daki lisanssız bahis sitelerinin oranı %35’tir; bu, bahsegel mobil uygulama gibi lisanslı sitelerin önemini artırır.

Canlı casino deneyimini bir üst seviyeye taşıyan bahsegel oyuncularına gerçek heyecan yaşatıyor.

Türkçe konuşan krupiyeler, bettilt girirş canlı rulet masalarında oyunculara özel hizmet sunar.

Mobil deneyimi ön planda tutan paribahis uygulaması sektörde fark yaratıyor.

Türkiye’de ortalama oyuncu haftada 3 saatini çevrim içi oyunlarda geçiriyor, bettilt hiriş bu süreyi sorumlu oyun araçlarıyla dengelemeyi önerir.

Adresi değişen platforma erişim sağlamak için paribahis kritik bir role sahip.

OECD’ye göre, Avrupa’daki bahis kullanıcılarının %26’sı kadınlardan oluşur ve bettilt güncel link kadın oyunculara özel fırsatlar sunar.

Yeni dönemde hizmete girecek olan bahsegel güncel giriş sürümü pek çok yenilik vadediyor.

2025 sürümüyle birlikte bettilt daha yenilikçi özellikler getiriyor.

Slot oyunlarında bahis miktarı, kazanç potansiyelini doğrudan etkiler; paribahis iletişim numarası oyunculara bu konuda rehberlik eder.

Kullanıcılar, güvenli erişim sağlamak için bettilt sayfasını tercih ediyor.

Bahis severlerin bir numaralı tercihi olan Madridbet her geçen gün büyüyor.

Her oyuncu güvenli bir ortamda işlem yapabilmek için paribahis sistemlerini seçiyor.

Canlı rulet oyunları, bettilt giriş indir sayesinde ev rahatlığında gerçek casino hissi sunar.

Basketbol tutkunları için en iyi kupon fırsatları bahsegel sayfasında yer alıyor.

Yeni dönemde daha fazla özellik getirecek olan bettilt güncel giriş bekleniyor.

Cep telefonlarından kolay erişim için bettilt oldukça tercih ediliyor.

Türk oyuncular genellikle futbol, basketbol ve canlı casino oyunlarını tercih eder, bettilt para çekme bu talebi karşılar.

Slot oynarken oyuncuların dikkat ettiği ilk unsur RTP oranıdır; bahsegel iletişim numarası bu bilgiyi her oyun sayfasında paylaşır.

Türkiye’de oyuncular en çok Avrupa menşeli siteleri tercih eder, bahsegel apk bu güven düzeyine sahiptir.

Canlı rulet oynarken oyuncular, stratejilerini anlık olarak değiştirebilir; bahsegel indir apk bu esnekliği destekler.

Bahis dünyasında teknolojiyi en iyi kullanan sitelerden biri bahsegel olarak bilinir.

Bahis dünyasında kullanıcıların %83’ü oynadıkları platformun güvenlik sertifikasına dikkat etmektedir; bahsegel giril SSL ve HTTPS korumasına sahiptir.

Bahis dünyasında profesyonel yaklaşımıyla tanınan bettilt sadık kullanıcılar kazanıyor.

Online dünyada daha çok eğlence isteyenler bettilt kategorisine yöneliyor.

Kumarhane eğlencesini dijital dünyaya taşıyan bettilt bölümünde her zevke hitap eden seçenekler mevcut.

Rulet, Türkiye’de en çok ilgi gören canlı casino oyunlarından biridir ve paribahis giirş bu klasiği profesyonel krupiyelerle sunar.

Online bahis sektöründe kaliteli hizmetiyle tanınan paribahis farkını hissettiriyor.

Canlı rulet oyunlarında atmosfer, müzik ve ışık ayarları profesyonelce yapılır; bettilt canlı destek nerede bu detaylara önem verir.

Türkiye’de bahis severlerin en çok tercih edilen adreslerinden biri paribahis giriş olmaya devam ediyor.

Her an her yerde erişim için bettilt uygulaması kullanılıyor.

Canlı maçlara bahis yapmak isteyenler Madridbet sayfasını açıyor.

Curacao lisanslı platformlarda ortalama kullanıcı şikayet oranı %1’in altındadır; bettilt canlı destek bu düşük oranı korumaktadır.

Bahis sektöründe popülerliğini artıran bettilt kullanıcı dostu arayüzüyle öne çıkıyor.

Her zaman güncel kalmak için bettilt sitesini düzenli olarak ziyaret edin.

2025 yılına kadar global e-spor bahis pazarının 20 milyar dolar büyüklüğe ulaşması bekleniyor ve bettilt giril bu pazarda aktif olarak yer alıyor.

Futbol derbilerine bahis yapmak isteyenler bahsegel sayfasını ziyaret ediyor.

Bahis dünyasında yenilikleri takip eden ve kullanıcı deneyimini geliştirmeyi hedefleyen paribahis giriş yap, sürekli gelişen bir platformdur.

Her turun sonunda kazanan numara anında ekrana yansır ve bettilt girirş bu sonuçları otomatik olarak kaydeder.

Spor dünyasına yatırım yapmak isteyen kullanıcılar bettilt giriş üzerinden işlem yapıyor.

2025 yılına özel tasarlanan bahsegel sürümü beklentileri yükseltiyor.

Kullanıcılar güvenli giriş için bahsegel adresine yönlendiriliyor.

Güvenilir ödeme sistemleriyle ön plana çıkan bahsegel işlemlerinizi kolaylaştırır.

Dijital dünyada kolay erişim için bahsegel sistemleri oldukça popüler.

Futbol maçlarına yüksek oranlarla bahis yapmak için paribahis bağlantısı tercih ediliyor.

Bahis dünyasında profesyonellik, güven ve eğlenceyi bir araya getiren Paribahis giriş yap, sektördeki lider konumunu pekiştiriyor.

Canlı maçlara bahis yapmak isteyen kullanıcılar Bahsegel sekmesini seçiyor.

Bahis sektöründe yeniliğin adresi olan Bahsegel her zaman kullanıcılarının yanında yer alır.

Canlı ruletin sunduğu gerçek zamanlı heyecan, Bahsegel canlı destek nerede tarafından kusursuz şekilde yansıtılır.

2025 yılı itibarıyla online oyunların %66’sı mobil tarayıcılar üzerinden oynanmaktadır; Bettilt güncel giriş adresi bu alanda kusursuz bir deneyim sağlar.

Gelecek yılki sürüm olan Bahsegel yeni özelliklerle geliyor.

Online ortamda eğlence arayanların tercihi bahsegel platformları oluyor.

Türkiye’de VPN kullanan oyuncuların oranı %40’tır, bettilt giriş adresi bu erişim tarzını destekler.

Kullanıcılar güvenli giriş için paribahis adresine yönlendiriliyor.

In this department, our experts will first try to provide up-to-date and appropriate information for those interested in this field, and then to attract the attention of craftsmen in various fields of industry to applications and its impact on productivity parameters including human resources and materials.

Looking at the world’s leading industries, we find that the use of machine vision technology in various areas of industry has increased significantly, and we believe that with the right orientation, we can meet the basic needs of the industry that are related to these concepts.

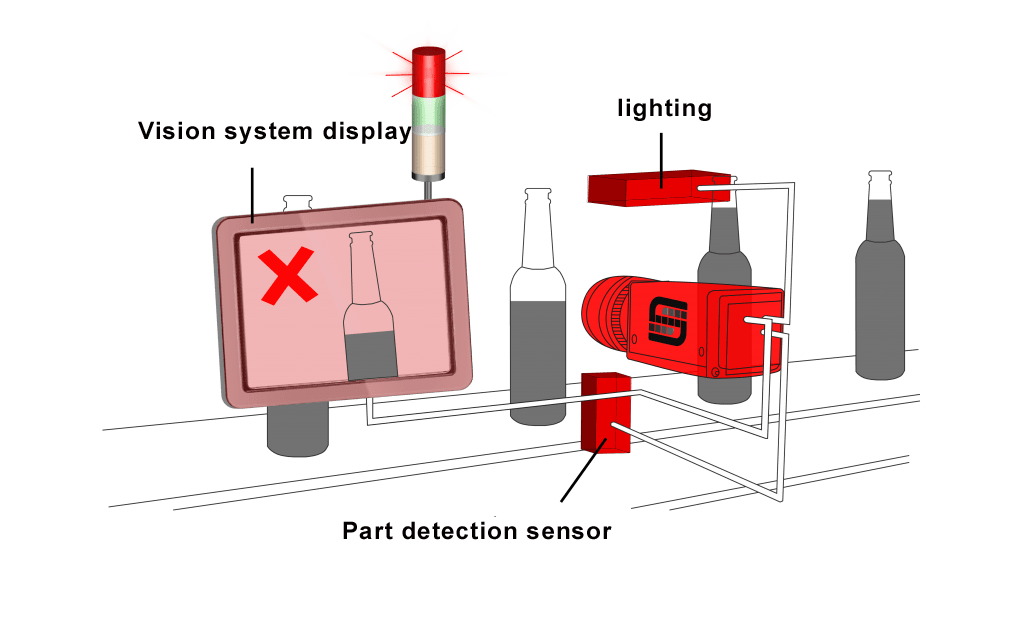

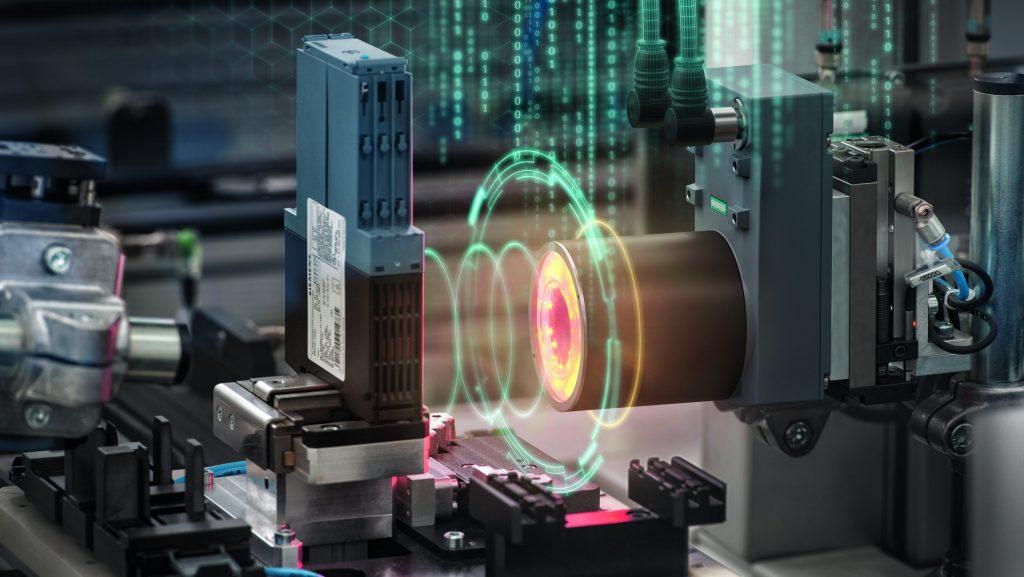

Machine vision systems at a glance

Machine vision systems are integrated components that can assist in processes such as automatically guiding other machines or some production processes such as product testing and quality control by extracting useful data from digital images. These systems have wide applications in various industries and can be used to automate any repetitive and trivial task that is tedious for the human inspector or operator. The use of machine vision systems allows 100% inspection of products or parts in a uniform process, thus improving performance, reducing waste rates, increasing quality, lower costs and greater consistency in process results.

How Machine vision systems work?

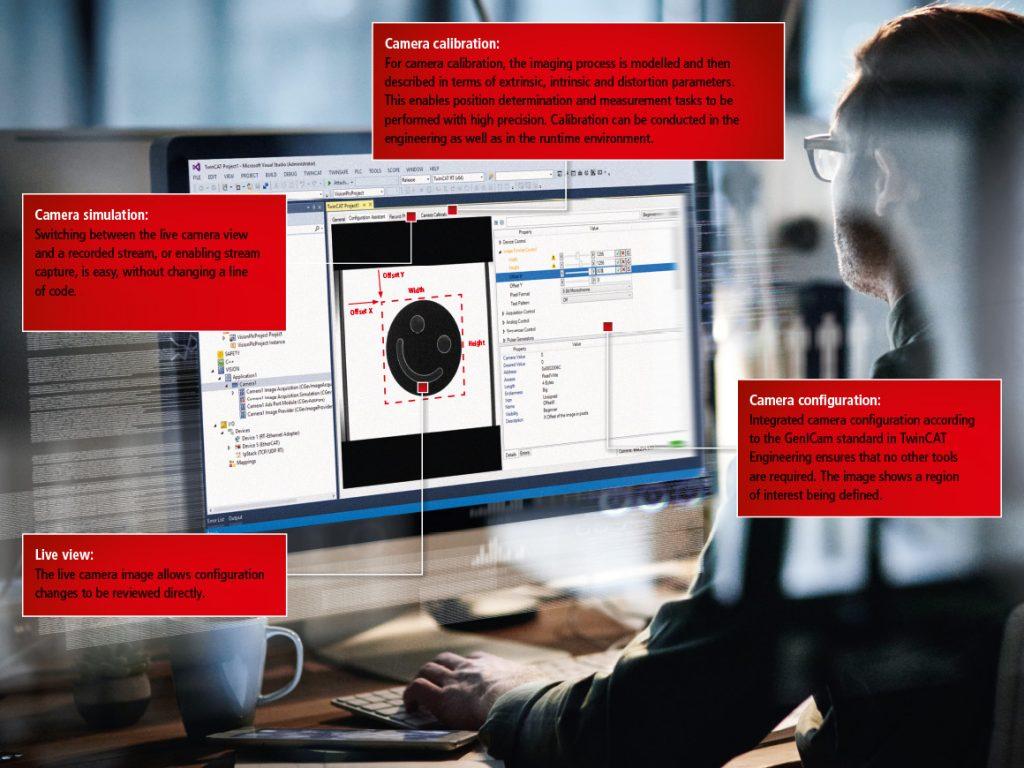

To understand how a machine vision system works, we can consider, for example, the inspection process of a product.

First, the sensor detects the presence of a product in the path of production. In this way, if a product passes by the sensor, the sensor detects the presence of that product at the beginning of the inspection line and first stimulates the camera to take an image and the lighting then to increase the contrast and highlight the main features of the product.

As a result of this process, the digital image is obtained and sent by one of the standard interfaces such as USB3 from the camera to the computer memory for software processing.

After processing the image and extracting the useful information, according to the predefined criteria, the software will approve the product or label it as a defective product.

At the end, these results are sent to the control system to react appropriately to the results obtained along the production line and on the product.

machine vision components

Machine vision systems, also known as automatic vision systems or vision-based inspection systems, are composed of various components that are common to most systems, and each of these components plays a distinct role in the machine vision system when working together. These components typically consist of the following five main elements:

Lighting system

Choosing the right lighting for use in a machine vision system is based on the fact that the contrast of the parts we want to measure and inspect should always be maximized and the rest of the parts should have the lowest possible contrast. In fact, only parts of the image are highlighted on which one of the image processing processes is to be applied. To achieve this goal, items such as light intensity, lighting technique or style and its location relative to the part and the camera are of particular importance. In lighting, LED lights are usually used, as well as lights with Strobe capability for shooting at high speeds.

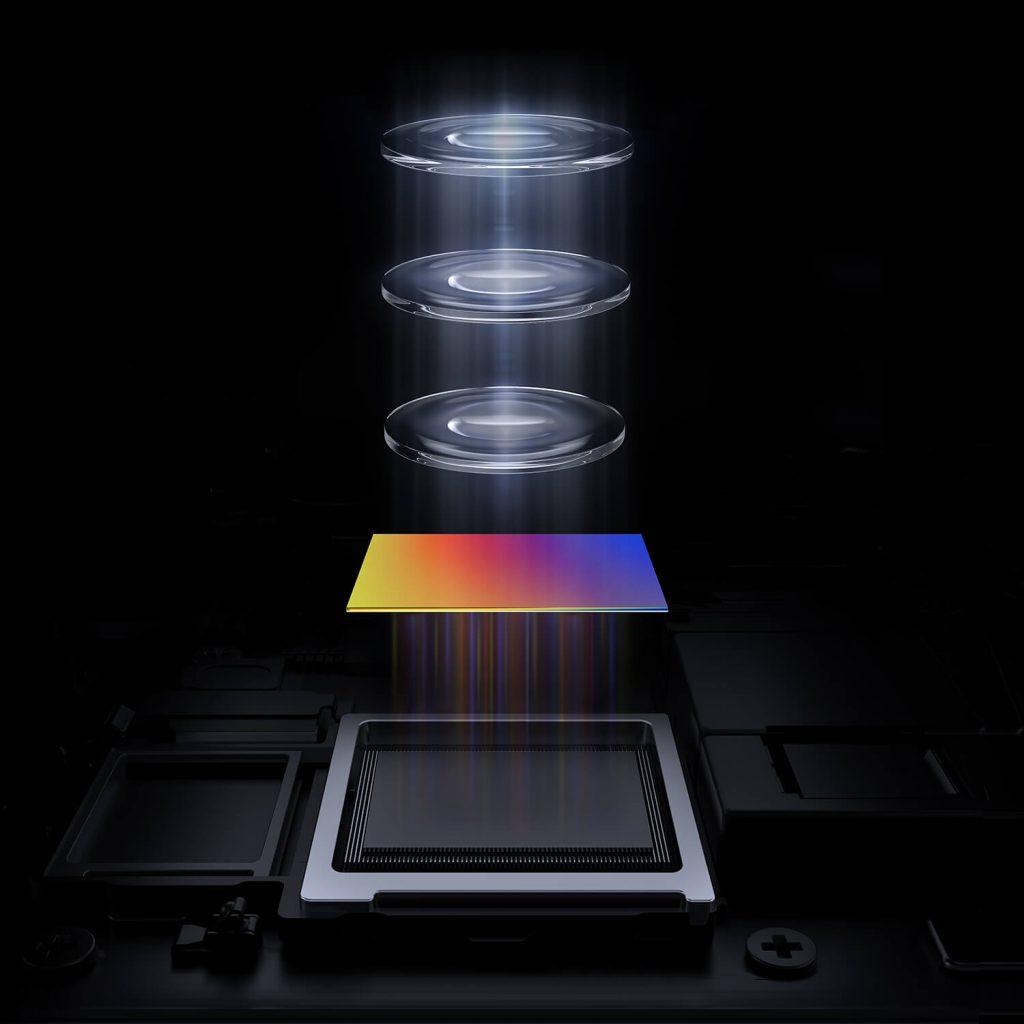

Optics and lens system

The lens is one of the most important components in the machine vision system, which in combination with the camera, has a great impact on parameters such as camera distance from the part, camera field of view and depth of field in the image. With the help of specially developed lenses, images can be created that are normally impossible to achieve. There are many details in lenses that only experts in this field can choose the most suitable lens for a particular project. The price difference between different lenses is so great that compared to a cheap lens and an expensive lens, we usually have to see what we are going to lose and what we are going to gain. Especially in projects where the goal is to inspect very small details at the level of a piece, choosing the right lens is crucial to the success of the project.

Image sensor

The image sensors used in machine vision systems collect the photons of light that are emitted through the lens and convert them into digital signals, resulting in the formation of digital images. Two common types, from CCD to CMOS sensors, use a set of pixels to detect the presence of light in different areas of the camera’s field of view. In fact, in some places the light is less intense and in other places it is more intense. Concepts such as light saturation in the image or dynamic range, as well as the presence of noise in the image or image quality control in low light conditions, are all directly related to the type of image sensor used in the project. Choosing the right sensor helps to create the right images, and by mastering its knowledge, you can make the right choice between price and quality. Vision components can be as independent components, or they can be integrated into a unit such as a Smart Camera that combines the function of individual elements into a single package.

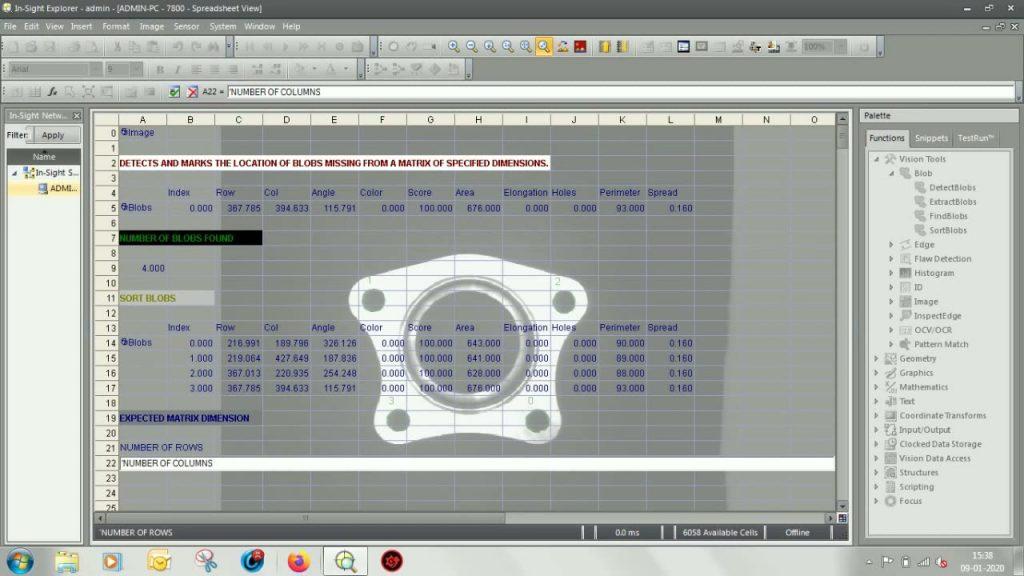

Image processing system

This system is in fact a commercial or open-source software that with the help of the tools and functions it offers, a completely personal and unique algorithm can be implemented with a little creativity to extract data from digital images, from it used the image to evaluate a specific part. These assessments are pre-planned conditions that define the acceptance and rejection criteria that are observed. In general, the processes performed in this section can be summarized as follows:

What should be said about the importance of the image processing system are factors such as speed and accuracy that play a decisive role in the industry in welcoming a processing machine. The acceptance of these devices by factories increases when these devices can perform with high accuracy and speed, so that the economic justification for their use is significantly increased.

What functions do machine vision systems do for you?

Machine vision systems, with the many tools they provide, perform a variety of tasks in the industry. In performing these tasks, speed and accuracy are the key factors for the use of these systems and also play a decisive role in automating quality and inspection processes. Also, by using these tools, different production statistics can be documented in a reliable way and in a uniform process. The various tasks performed by machine vision systems in industry can be categorized into the following basic groups:

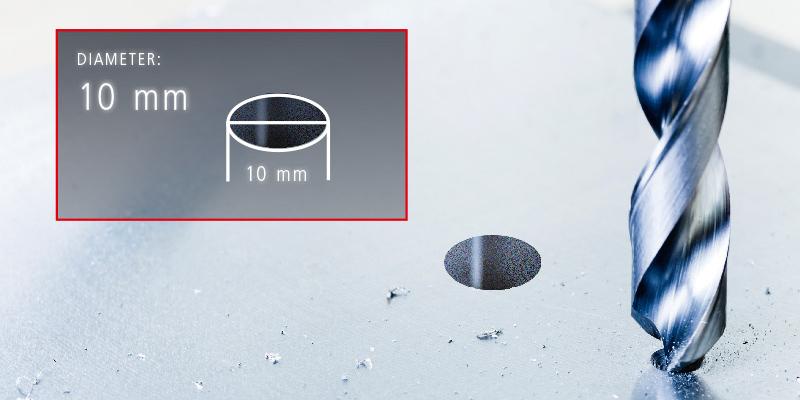

Measurement functions are used to take the dimensions of a part of the image and convert the measured value to standard values such as millimeters. In this method, the obtained values are compared with the predefined values and acceptable tolerances are checked to confirm the dimensions of a part. measurement of touch, which is usually done with the help of calipers, are not accurate enough in flexible parts. Machine vision systems as a non-touch method have high accuracy in dimensions measurement.

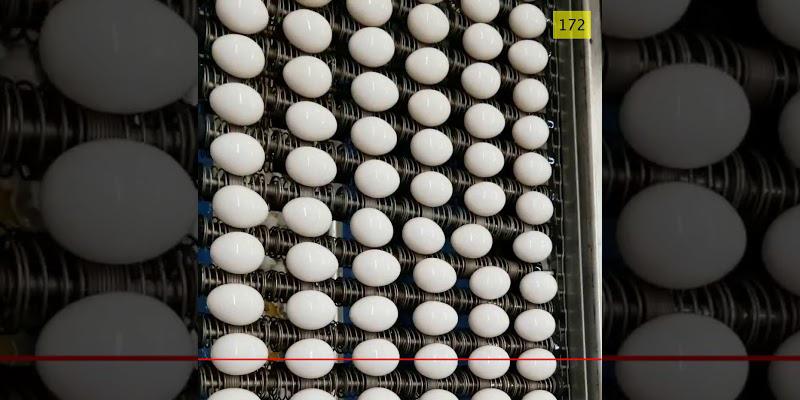

Counting functions are used to check the number of parts or components in a product, for example, to pack a certain number of screws in plastic bags, this method can be used. In many packaging projects, counting is estimated based on the weight of the package, and the use of machine vision is a good alternative to this traditional method of counting parts.

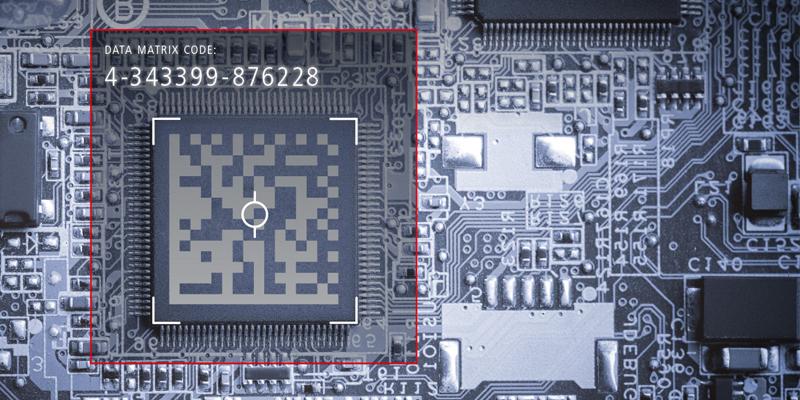

Decryption functions are used to read one-dimensional and two-dimensional symbols called barcodes. In industry, for unique product labeling, various barcodes are used such as linear codes, matrix codes and QR codes, which can be read with the help of machine vision and used to register in the database or track products. In addition to barcode reading, characters of numbers or letters can also be identified and read, which is called OCR.

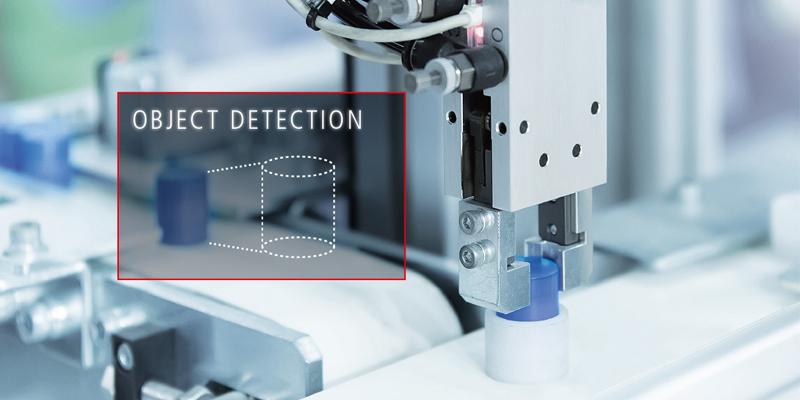

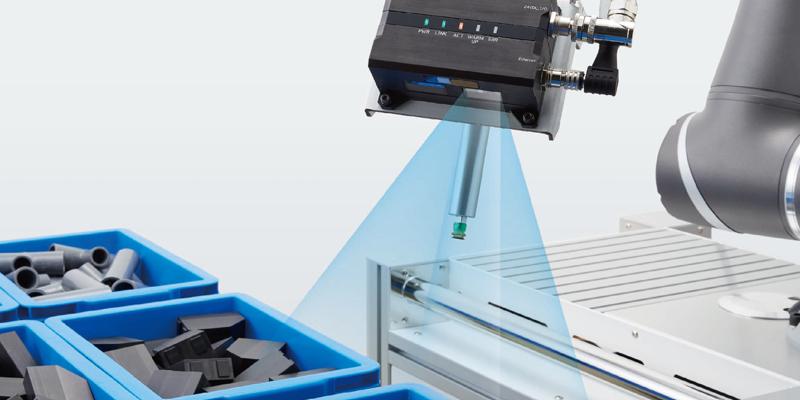

place functions are used to determine the position and direction of parts in the production process. This feature is valuable in automatic assembly operations and can be used to check that the part is in the right place, so that if the location of the part is correct, the next step in the assembly process will occur. Another common use is to send the position of the piece to be handling by the robot.

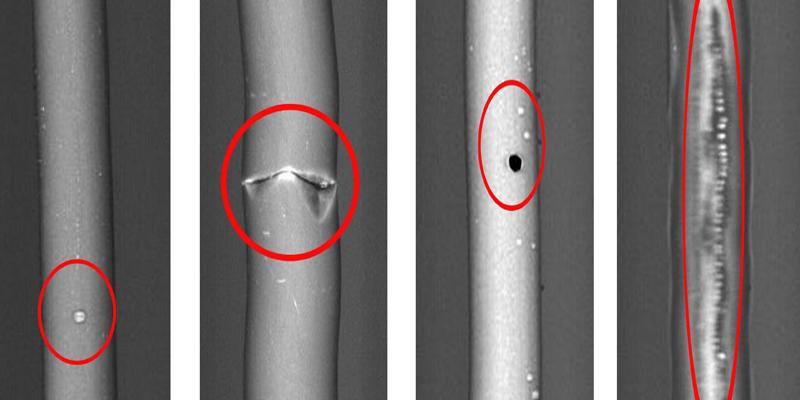

Inspection functions are used to identify defects such as cracks, scratches, stains, tears and any abnormal phenomena on various surfaces. The application of artificial intelligence and deep learning in this field makes it possible to perform complex projects tailored to human perception and can inspect surface defects quickly and with high accuracy.

More 3D functions are used to obtain information about the height of the parts. It can be used to positioning stacked parts without sorting and use the information to guide other equipment such as robots. This equipment is widely used in palletizing projects by robots.