OECD 2024 raporuna göre, Avrupa’daki lisanssız bahis sitelerinin oranı %35’tir; bu, bahsegel mobil uygulama gibi lisanslı sitelerin önemini artırır.

Canlı casino deneyimini bir üst seviyeye taşıyan bahsegel oyuncularına gerçek heyecan yaşatıyor.

Türkçe konuşan krupiyeler, bettilt girirş canlı rulet masalarında oyunculara özel hizmet sunar.

Mobil deneyimi ön planda tutan paribahis uygulaması sektörde fark yaratıyor.

Türkiye’de ortalama oyuncu haftada 3 saatini çevrim içi oyunlarda geçiriyor, bettilt hiriş bu süreyi sorumlu oyun araçlarıyla dengelemeyi önerir.

Adresi değişen platforma erişim sağlamak için paribahis kritik bir role sahip.

OECD’ye göre, Avrupa’daki bahis kullanıcılarının %26’sı kadınlardan oluşur ve bettilt güncel link kadın oyunculara özel fırsatlar sunar.

Yeni dönemde hizmete girecek olan bahsegel güncel giriş sürümü pek çok yenilik vadediyor.

2025 sürümüyle birlikte bettilt daha yenilikçi özellikler getiriyor.

Slot oyunlarında bahis miktarı, kazanç potansiyelini doğrudan etkiler; paribahis iletişim numarası oyunculara bu konuda rehberlik eder.

Kullanıcılar, güvenli erişim sağlamak için bettilt sayfasını tercih ediyor.

Bahis severlerin bir numaralı tercihi olan Madridbet her geçen gün büyüyor.

Her oyuncu güvenli bir ortamda işlem yapabilmek için paribahis sistemlerini seçiyor.

Canlı rulet oyunları, bettilt giriş indir sayesinde ev rahatlığında gerçek casino hissi sunar.

Basketbol tutkunları için en iyi kupon fırsatları bahsegel sayfasında yer alıyor.

Yeni dönemde daha fazla özellik getirecek olan bettilt güncel giriş bekleniyor.

Cep telefonlarından kolay erişim için bettilt oldukça tercih ediliyor.

Türk oyuncular genellikle futbol, basketbol ve canlı casino oyunlarını tercih eder, bettilt para çekme bu talebi karşılar.

Slot oynarken oyuncuların dikkat ettiği ilk unsur RTP oranıdır; bahsegel iletişim numarası bu bilgiyi her oyun sayfasında paylaşır.

Türkiye’de oyuncular en çok Avrupa menşeli siteleri tercih eder, bahsegel apk bu güven düzeyine sahiptir.

Canlı rulet oynarken oyuncular, stratejilerini anlık olarak değiştirebilir; bahsegel indir apk bu esnekliği destekler.

Bahis dünyasında teknolojiyi en iyi kullanan sitelerden biri bahsegel olarak bilinir.

Bahis dünyasında kullanıcıların %83’ü oynadıkları platformun güvenlik sertifikasına dikkat etmektedir; bahsegel giril SSL ve HTTPS korumasına sahiptir.

Bahis dünyasında profesyonel yaklaşımıyla tanınan bettilt sadık kullanıcılar kazanıyor.

Online dünyada daha çok eğlence isteyenler bettilt kategorisine yöneliyor.

Kumarhane eğlencesini dijital dünyaya taşıyan bettilt bölümünde her zevke hitap eden seçenekler mevcut.

Rulet, Türkiye’de en çok ilgi gören canlı casino oyunlarından biridir ve paribahis giirş bu klasiği profesyonel krupiyelerle sunar.

Online bahis sektöründe kaliteli hizmetiyle tanınan paribahis farkını hissettiriyor.

Canlı rulet oyunlarında atmosfer, müzik ve ışık ayarları profesyonelce yapılır; bettilt canlı destek nerede bu detaylara önem verir.

Türkiye’de bahis severlerin en çok tercih edilen adreslerinden biri paribahis giriş olmaya devam ediyor.

Her an her yerde erişim için bettilt uygulaması kullanılıyor.

Canlı maçlara bahis yapmak isteyenler Madridbet sayfasını açıyor.

Curacao lisanslı platformlarda ortalama kullanıcı şikayet oranı %1’in altındadır; bettilt canlı destek bu düşük oranı korumaktadır.

Bahis sektöründe popülerliğini artıran bettilt kullanıcı dostu arayüzüyle öne çıkıyor.

Her zaman güncel kalmak için bettilt sitesini düzenli olarak ziyaret edin.

2025 yılına kadar global e-spor bahis pazarının 20 milyar dolar büyüklüğe ulaşması bekleniyor ve bettilt giril bu pazarda aktif olarak yer alıyor.

Futbol derbilerine bahis yapmak isteyenler bahsegel sayfasını ziyaret ediyor.

Bahis dünyasında yenilikleri takip eden ve kullanıcı deneyimini geliştirmeyi hedefleyen paribahis giriş yap, sürekli gelişen bir platformdur.

Her turun sonunda kazanan numara anında ekrana yansır ve bettilt girirş bu sonuçları otomatik olarak kaydeder.

Spor dünyasına yatırım yapmak isteyen kullanıcılar bettilt giriş üzerinden işlem yapıyor.

2025 yılına özel tasarlanan bahsegel sürümü beklentileri yükseltiyor.

Kullanıcılar güvenli giriş için bahsegel adresine yönlendiriliyor.

Güvenilir ödeme sistemleriyle ön plana çıkan bahsegel işlemlerinizi kolaylaştırır.

Dijital dünyada kolay erişim için bahsegel sistemleri oldukça popüler.

Futbol maçlarına yüksek oranlarla bahis yapmak için paribahis bağlantısı tercih ediliyor.

Bahis dünyasında profesyonellik, güven ve eğlenceyi bir araya getiren Paribahis giriş yap, sektördeki lider konumunu pekiştiriyor.

Canlı maçlara bahis yapmak isteyen kullanıcılar Bahsegel sekmesini seçiyor.

Bahis sektöründe yeniliğin adresi olan Bahsegel her zaman kullanıcılarının yanında yer alır.

Canlı ruletin sunduğu gerçek zamanlı heyecan, Bahsegel canlı destek nerede tarafından kusursuz şekilde yansıtılır.

2025 yılı itibarıyla online oyunların %66’sı mobil tarayıcılar üzerinden oynanmaktadır; Bettilt güncel giriş adresi bu alanda kusursuz bir deneyim sağlar.

Gelecek yılki sürüm olan Bahsegel yeni özelliklerle geliyor.

Online ortamda eğlence arayanların tercihi bahsegel platformları oluyor.

Türkiye’de VPN kullanan oyuncuların oranı %40’tır, bettilt giriş adresi bu erişim tarzını destekler.

Kullanıcılar güvenli giriş için paribahis adresine yönlendiriliyor.

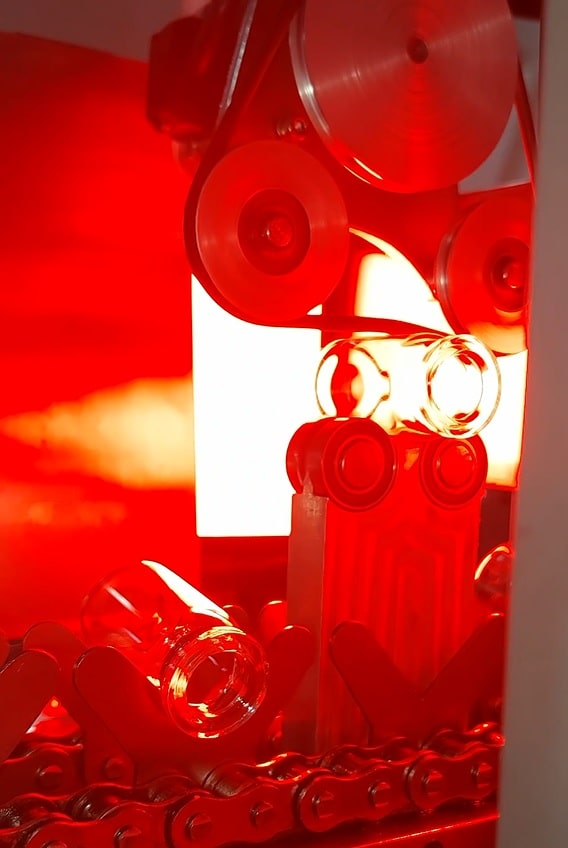

a vial is a small container usually made of glass or plastic. It may be shaped like a tube or bottle and have a flat bottom, unlike common blood collection tubes. Vials are available with various caps to meet specific storage or handling requirements. Vials are typically used to store medicines or laboratory samples.

One of the positive points of using a glass vial is its durability and small size. Also, because the glass vial has anti-chemical properties, it is a perfect option for storing some medicines, and all the properties of the medicines are completely preserved in the glass vials.

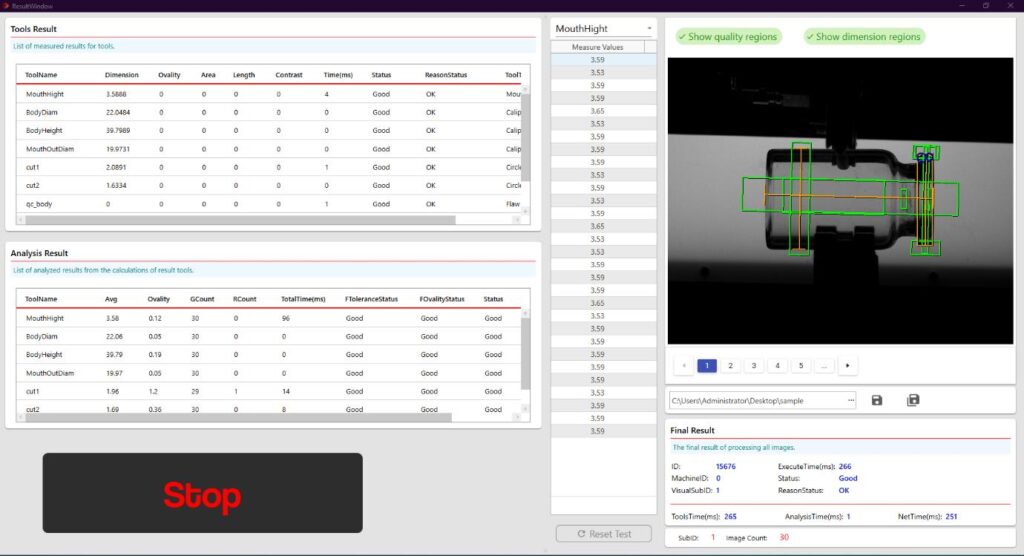

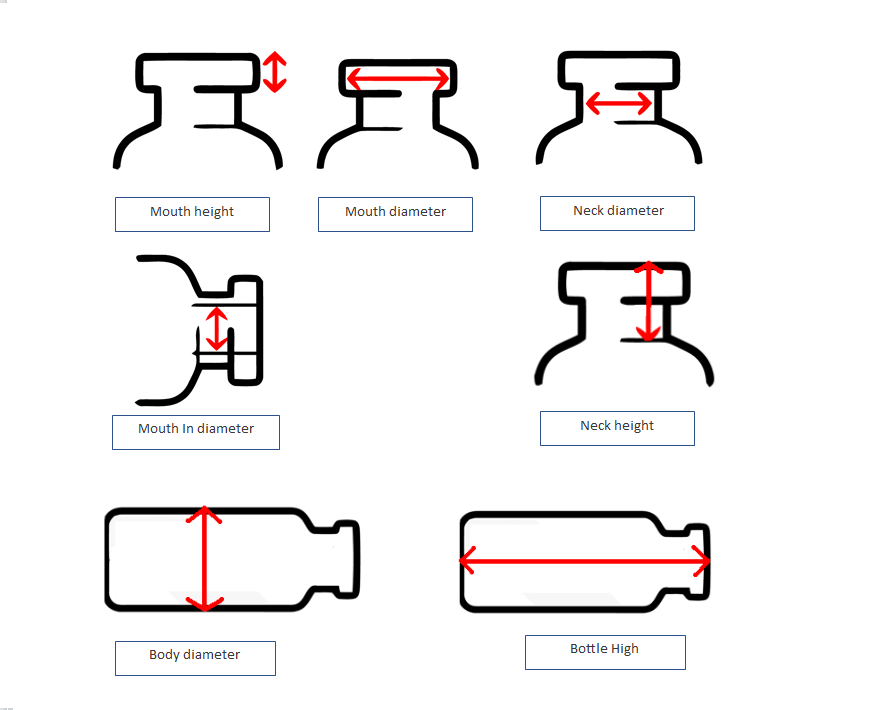

A COMPLETE VIAL QUALITY INSPECTION

When it comes to tubular glass production for the pharmaceutical industry, high standards are put in place to ensure that products are capable of performing specific, critical functions.

Vials play an important role in pharmaceutical packaging. If contamination, cosmetic or geometric defects compromise your production, they can have a decisive impact on the integrity of the vials you produce.

To eliminate defects in your products, hit consistent quality control standards, and meet customer requirements, you need a comprehensive vial quality control solution.

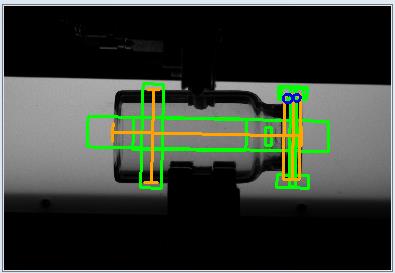

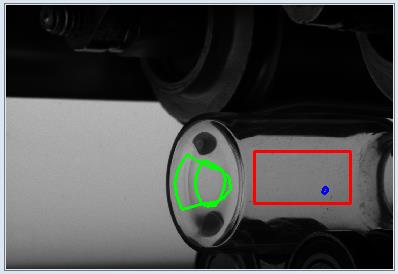

Vision inspection systems for pharmaceutical glass vials can detect dimensional or cosmetic defects. It can also help control the tight tolerances on vial geometry to ensure premium quality. 100% vision inspection can detect “visible” defects even when very small. The high-end Vision systems can detect even invisible defects like missing pieces of material, deformations and contamination. These defects can even be embedded in the material.

High speed, 100% vision inspection can detect defects even when less visible and 100 um or smaller in size. High-end systems available can even detect invisible defects that are embedded in product itself or too small to see with the human eye.

The most reliable non-contact method for the highest level of quality control

With the help of machine vision technology, different types of inspections can be defined for pharmaceutical products. By mechanizing the quality control process of products, it is possible to experience a significant increase in the speed of inspections without human error, and apart from that, the quality process of products can be managed in useful statistical formats

Appearance and size inspection system using machine vision system

Currently, camera-based image inspection is commonly used. However, there were many challenges to overcome, such as reflection of light or unevenness of glass texture, before applying it to formed glassware. Sorinfarbod has been striving more than 4 years to solve these issues one by one, which improved the performance not just for dimension and shape checks, but to the level “more reliable than human eyes”.

Diameter and height of the total vial or parts like the body, brim, neck or lip can be measured ensure dimensional and quality physical and chemical compliance to specifications.

• Automatic rejection of defective pcs

• Customizable quality level

• Automatic calibration system

• Performance per chuck

• Measurements and statistics in real time

Functions

• Simple teaching of new or modified test instructions

• Inspection of the test specimen on the basis of visual characteristics

• Reporting of detected errors

• Marking of the faulty areas on the screen

False Rejects—No Thanks!

Defective vials are filtered out at an early stage to prevent them reaching further processing. This is an important cost factor for you, as it prevents defective containers from being filled with costly pharmaceuticals.

With this machine, high-powered cameras and intelligent algorithms reliably detect defects and keep false rejects to a minimum. But that’s not all. You can also use the inspection data collected for analysis and process optimization.