Welcome to the Industrial Robots Department of Sorin Farbod Company.

OECD 2024 raporuna göre, Avrupa’daki lisanssız bahis sitelerinin oranı %35’tir; bu, bahsegel mobil uygulama gibi lisanslı sitelerin önemini artırır.

Canlı casino deneyimini bir üst seviyeye taşıyan bahsegel oyuncularına gerçek heyecan yaşatıyor.

Türkçe konuşan krupiyeler, bettilt girirş canlı rulet masalarında oyunculara özel hizmet sunar.

Mobil deneyimi ön planda tutan paribahis uygulaması sektörde fark yaratıyor.

Türkiye’de ortalama oyuncu haftada 3 saatini çevrim içi oyunlarda geçiriyor, bettilt hiriş bu süreyi sorumlu oyun araçlarıyla dengelemeyi önerir.

Adresi değişen platforma erişim sağlamak için paribahis kritik bir role sahip.

OECD’ye göre, Avrupa’daki bahis kullanıcılarının %26’sı kadınlardan oluşur ve bettilt güncel link kadın oyunculara özel fırsatlar sunar.

Yeni dönemde hizmete girecek olan bahsegel güncel giriş sürümü pek çok yenilik vadediyor.

2025 sürümüyle birlikte bettilt daha yenilikçi özellikler getiriyor.

Slot oyunlarında bahis miktarı, kazanç potansiyelini doğrudan etkiler; paribahis iletişim numarası oyunculara bu konuda rehberlik eder.

Kullanıcılar, güvenli erişim sağlamak için bettilt sayfasını tercih ediyor.

Bahis severlerin bir numaralı tercihi olan Madridbet her geçen gün büyüyor.

Her oyuncu güvenli bir ortamda işlem yapabilmek için paribahis sistemlerini seçiyor.

Canlı rulet oyunları, bettilt giriş indir sayesinde ev rahatlığında gerçek casino hissi sunar.

Basketbol tutkunları için en iyi kupon fırsatları bahsegel sayfasında yer alıyor.

Yeni dönemde daha fazla özellik getirecek olan bettilt güncel giriş bekleniyor.

Cep telefonlarından kolay erişim için bettilt oldukça tercih ediliyor.

Türk oyuncular genellikle futbol, basketbol ve canlı casino oyunlarını tercih eder, bettilt para çekme bu talebi karşılar.

Slot oynarken oyuncuların dikkat ettiği ilk unsur RTP oranıdır; bahsegel iletişim numarası bu bilgiyi her oyun sayfasında paylaşır.

Türkiye’de oyuncular en çok Avrupa menşeli siteleri tercih eder, bahsegel apk bu güven düzeyine sahiptir.

Canlı rulet oynarken oyuncular, stratejilerini anlık olarak değiştirebilir; bahsegel indir apk bu esnekliği destekler.

Bahis dünyasında teknolojiyi en iyi kullanan sitelerden biri bahsegel olarak bilinir.

Bahis dünyasında kullanıcıların %83’ü oynadıkları platformun güvenlik sertifikasına dikkat etmektedir; bahsegel giril SSL ve HTTPS korumasına sahiptir.

Bahis dünyasında profesyonel yaklaşımıyla tanınan bettilt sadık kullanıcılar kazanıyor.

Online dünyada daha çok eğlence isteyenler bettilt kategorisine yöneliyor.

Kumarhane eğlencesini dijital dünyaya taşıyan bettilt bölümünde her zevke hitap eden seçenekler mevcut.

Rulet, Türkiye’de en çok ilgi gören canlı casino oyunlarından biridir ve paribahis giirş bu klasiği profesyonel krupiyelerle sunar.

Online bahis sektöründe kaliteli hizmetiyle tanınan paribahis farkını hissettiriyor.

Canlı rulet oyunlarında atmosfer, müzik ve ışık ayarları profesyonelce yapılır; bettilt canlı destek nerede bu detaylara önem verir.

Türkiye’de bahis severlerin en çok tercih edilen adreslerinden biri paribahis giriş olmaya devam ediyor.

Her an her yerde erişim için bettilt uygulaması kullanılıyor.

Canlı maçlara bahis yapmak isteyenler Madridbet sayfasını açıyor.

Curacao lisanslı platformlarda ortalama kullanıcı şikayet oranı %1’in altındadır; bettilt canlı destek bu düşük oranı korumaktadır.

Bahis sektöründe popülerliğini artıran bettilt kullanıcı dostu arayüzüyle öne çıkıyor.

Her zaman güncel kalmak için bettilt sitesini düzenli olarak ziyaret edin.

2025 yılına kadar global e-spor bahis pazarının 20 milyar dolar büyüklüğe ulaşması bekleniyor ve bettilt giril bu pazarda aktif olarak yer alıyor.

Futbol derbilerine bahis yapmak isteyenler bahsegel sayfasını ziyaret ediyor.

Bahis dünyasında yenilikleri takip eden ve kullanıcı deneyimini geliştirmeyi hedefleyen paribahis giriş yap, sürekli gelişen bir platformdur.

Her turun sonunda kazanan numara anında ekrana yansır ve bettilt girirş bu sonuçları otomatik olarak kaydeder.

Spor dünyasına yatırım yapmak isteyen kullanıcılar bettilt giriş üzerinden işlem yapıyor.

2025 yılına özel tasarlanan bahsegel sürümü beklentileri yükseltiyor.

Kullanıcılar güvenli giriş için bahsegel adresine yönlendiriliyor.

Güvenilir ödeme sistemleriyle ön plana çıkan bahsegel işlemlerinizi kolaylaştırır.

Dijital dünyada kolay erişim için bahsegel sistemleri oldukça popüler.

Futbol maçlarına yüksek oranlarla bahis yapmak için paribahis bağlantısı tercih ediliyor.

Bahis dünyasında profesyonellik, güven ve eğlenceyi bir araya getiren Paribahis giriş yap, sektördeki lider konumunu pekiştiriyor.

Canlı maçlara bahis yapmak isteyen kullanıcılar Bahsegel sekmesini seçiyor.

Bahis sektöründe yeniliğin adresi olan Bahsegel her zaman kullanıcılarının yanında yer alır.

Canlı ruletin sunduğu gerçek zamanlı heyecan, Bahsegel canlı destek nerede tarafından kusursuz şekilde yansıtılır.

2025 yılı itibarıyla online oyunların %66’sı mobil tarayıcılar üzerinden oynanmaktadır; Bettilt güncel giriş adresi bu alanda kusursuz bir deneyim sağlar.

Gelecek yılki sürüm olan Bahsegel yeni özelliklerle geliyor.

Online ortamda eğlence arayanların tercihi bahsegel platformları oluyor.

Türkiye’de VPN kullanan oyuncuların oranı %40’tır, bettilt giriş adresi bu erişim tarzını destekler.

Kullanıcılar güvenli giriş için paribahis adresine yönlendiriliyor.

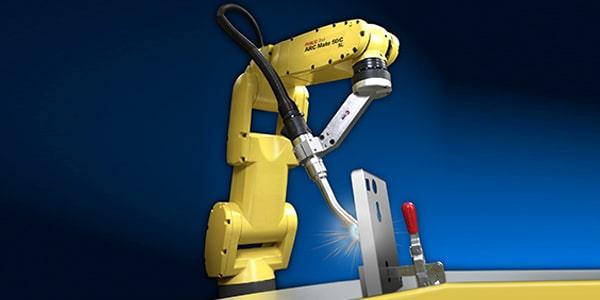

Industrial Robots Department

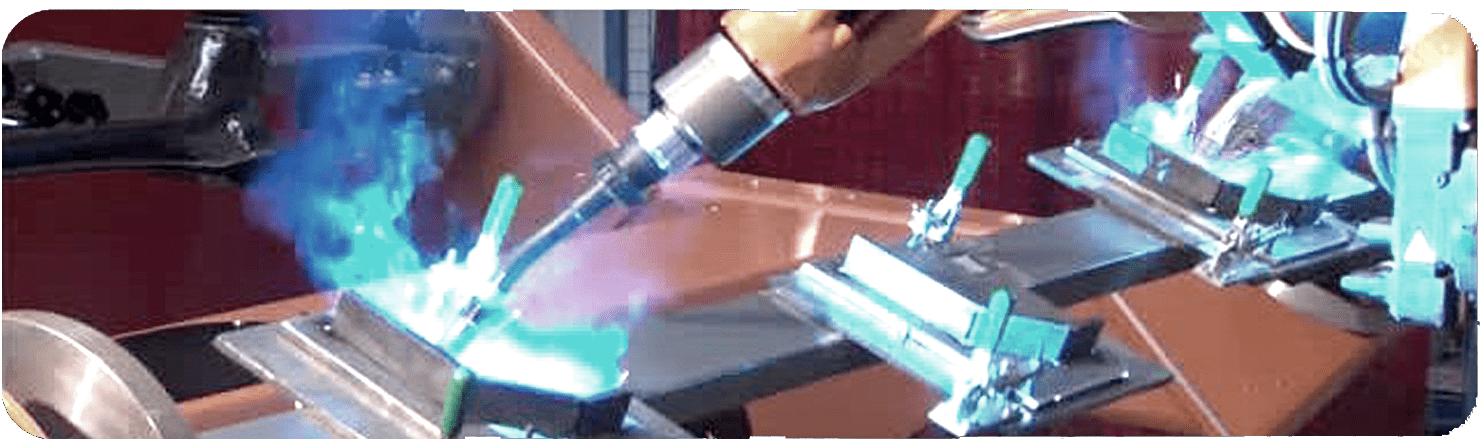

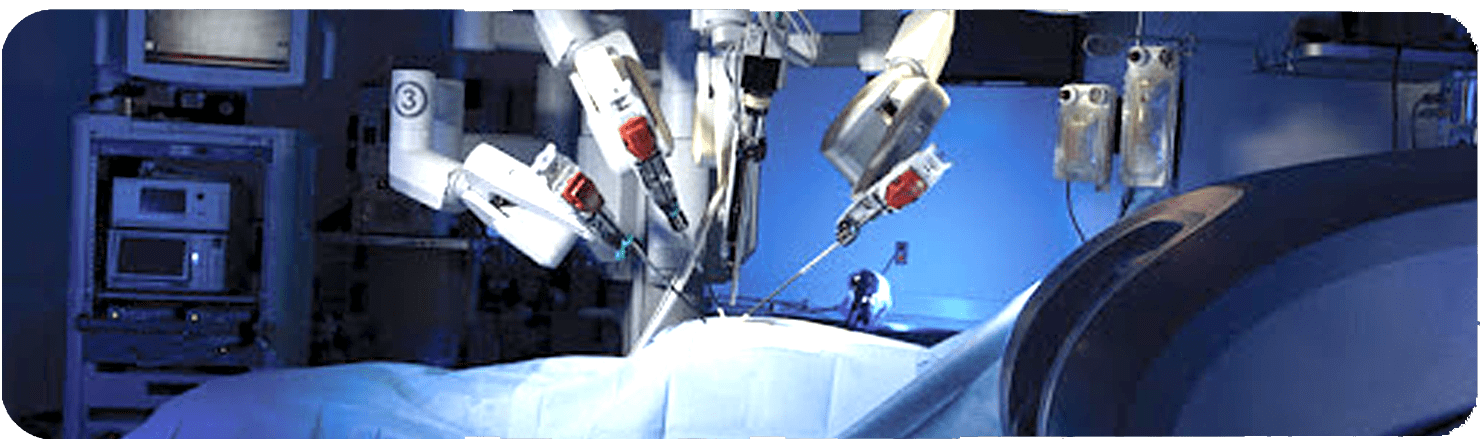

Given the new definitions in industrial technology, it can be predicted that the industry will start a new decade. In the last 10 years, significant advances have been made in the field of industrial robots and the technologies used in them, as well as production line technologies.

Given the astonishing advances we have seen in this decade, it looks like we will see more changes in industrial robots in the next 10 years. In Iran, due to the significant increase and growth of products of various factories, the need for heavy production lines to use industrial robots is felt more than ever.

In Sorin Farbod Industrial Robots Department, we try to draw the attention of Iranian craftsmen more than ever to justify the use of robotic lines and related technologies, and in this regard, our experts provide various services of consulting and informing about new processes from the implementation and development of robotic cells to those interested in this industrial field.

Sorin Farbod Company, based on its organizational mission, is proud to inform the companies present in this industrial cycle of the trends and innovations developed in it, and as a knowledge-based company to help meet the technological needs of the country’s industry.

One aspect of innovation in industrial robots can be seen in its programming, since the most robust and versatile robots are virtually nothing without effective programming, which is why many engineers and developers of industrial robots focus on better design of software in this area.

Another aspect of technology is artificial intelligence, which today is a pivotal development for almost every industry and holds special promise for robotics and automation. Combining artificial intelligence with advanced robotic systems has advanced automated manufacturing processes through sophisticated machine learning to a high level of machine intelligence. But no matter what the future holds for robotics production and inspection, companies will have no choice but to move to these growing technologies to increase productivity and competitiveness, and is better that they will move in this direction with reliable and experienced consultants.

The experts of Sorin Farbod Company, with more than a decade of experience in implementing robotic projects and specializing in the use of artificial intelligence, are ready to provide a wide range of services in this industrial field. In the following, you will get acquainted with the concept of robotic cells and the justification for their use.

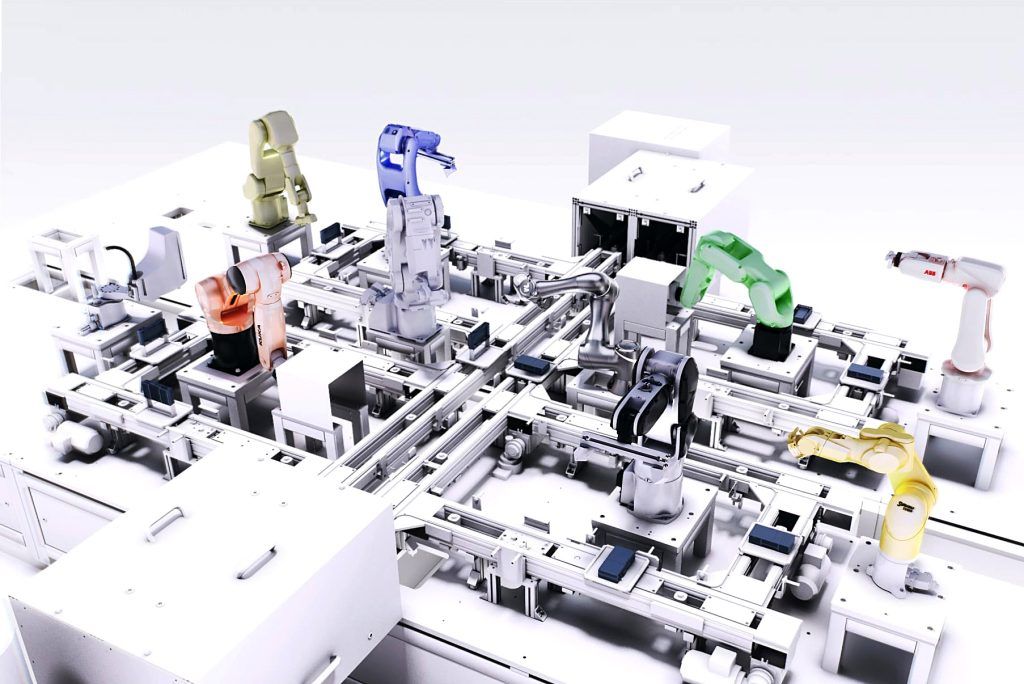

What is a robotic cell?

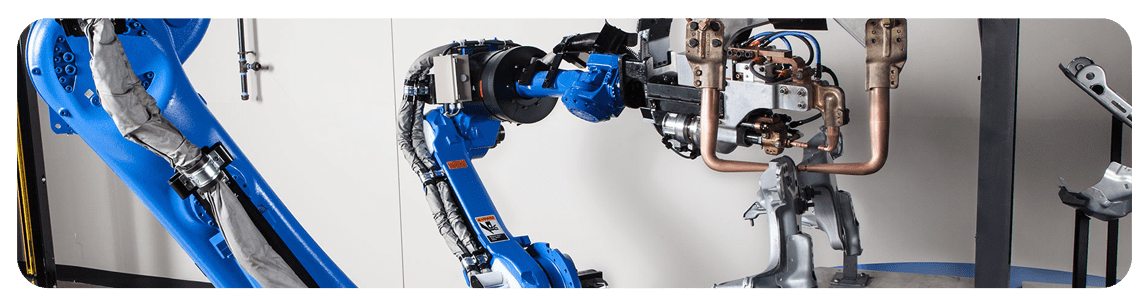

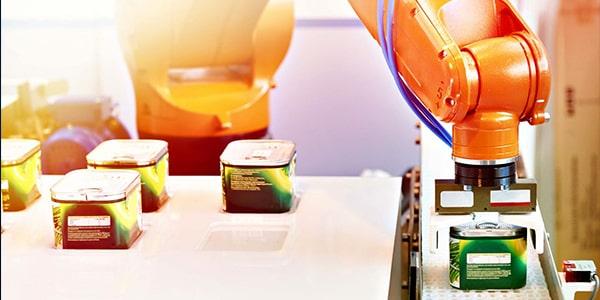

A robotic cell is one or a set of robots that do things automatically in a cell. The goal of these robots is to maximize, accelerate and simplify a complete production module and achieve high levels of product quality repetition.

These automated systems have a very high degree of independence. Keep in mind that robots can cover night shifts and holidays without human intervention. They never get sick and do not go on vacation!

Robotic cells allow companies to operate twice work hours as traditional operators during working weeks!

Thus, while initial investment may be significant, it provides the rapid return on investment (ROI) that is essential for managers with budget constraints. In our experience, a well-designed robotic cell is less than a year return on investment.

What do robotic cells do for you?

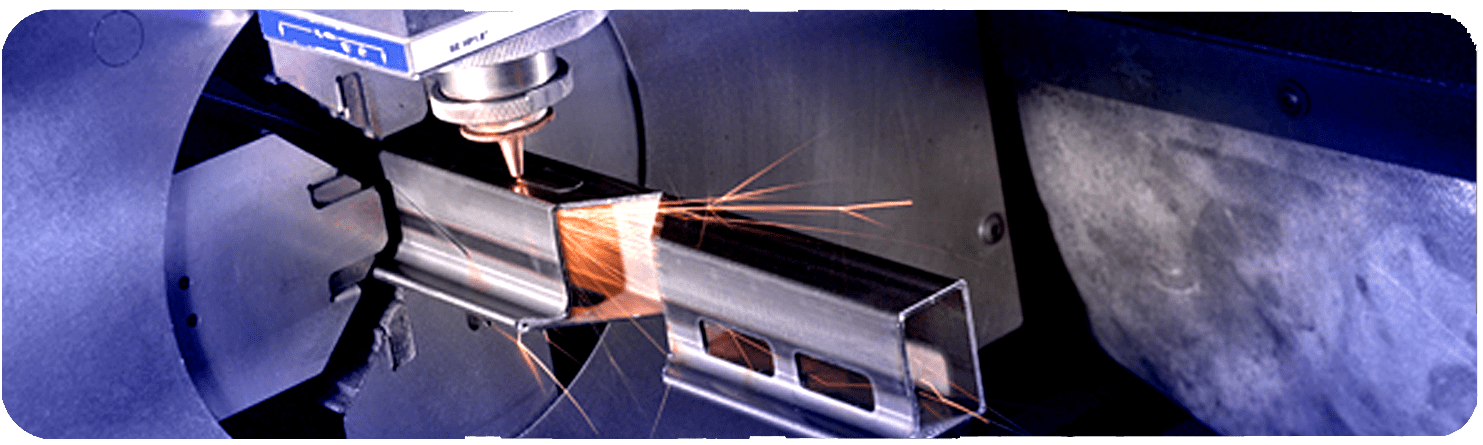

Robotic cells are used to automate various operations in many manufacturing sectors. In performing these tasks, speed and accuracy are key factors for the application of these systems and also play a decisive role in automating quality and inspection processes. Also, by using these tools, different production statistics can be documented in a reliable way and in a uniform process. The various tasks that robotic cells perform in industry can be categorized into the following basic groups:

As mentioned above, this type of robotic automation is used in any industrial field (automotive, aviation, mechanics, medicine, food, etc.). No matter what the task of a robotic cell, the output will be accurate and reliable.

In addition to being a highly efficient system, robotic cells have tremendous flexibility, so by changing the type of process, you can easily reprogram the robots without making major changes. In addition, if the company needs to switch from one type of process to another, robot cells can change very fast and efficient.

Robots and Industry 4.0

Industry 4.0, also known as the Internet Of Things (IOT), is changing the way manufacturers work around the world. The ability to collect, analyze and act on production data, especially in terms of efficiency and continuous optimization, has a transformative effect on operations.

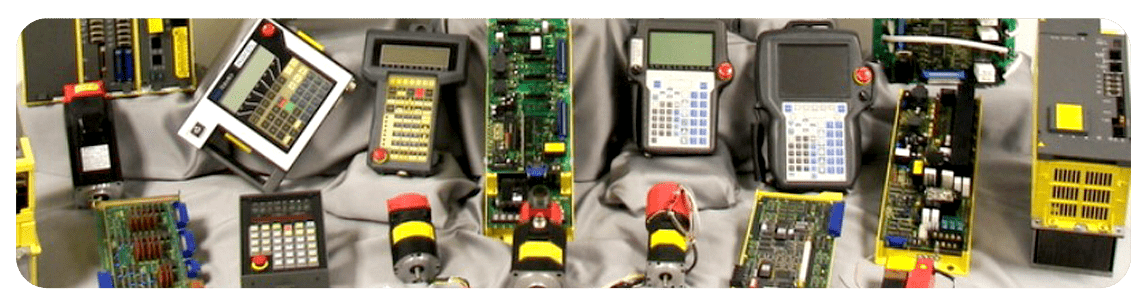

For smarter device management, robot cells can also be equipped with a system for collecting, storing and processing generated data. This software usually uses a router, which also allows you to troubleshoot and remotely control the robot cell.

The high level of technology obtained through this data storage and control system enables it to meet the needs of the 4.0 industry.

Why choose Sorin Farbod to design and execute your robotic projects?

Innovative robotic solutions that enable you to produce effectively now and, in the future

Sorin Farbod offers a wide range of automated solutions for your products, always focusing on efficiency and process improvement. Our solutions that can be installed separately on machines or production lines or can be fully customized to responsiveness customer needs, and ensure that they optimize the production process and increase the value of human resources.

Process knowledge

Experienced robotics specialists (about 12 years of experience)

Engineering and design

Installation and programming

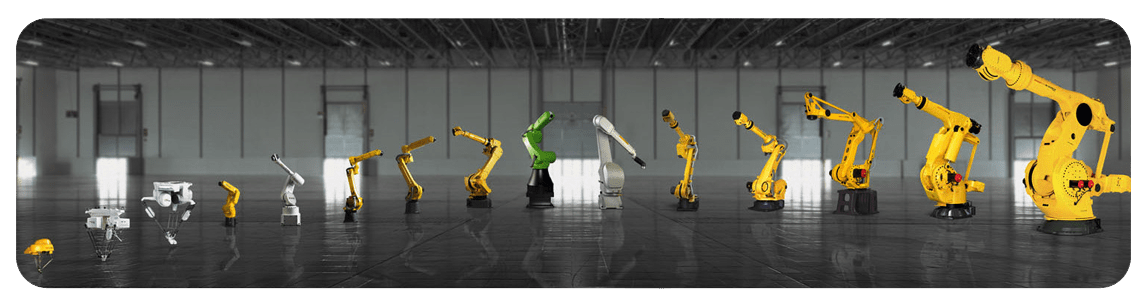

Cooperation with KUKA, FANUC, ABB and Yaskawa brands

Specialization in multi-robot custom systems

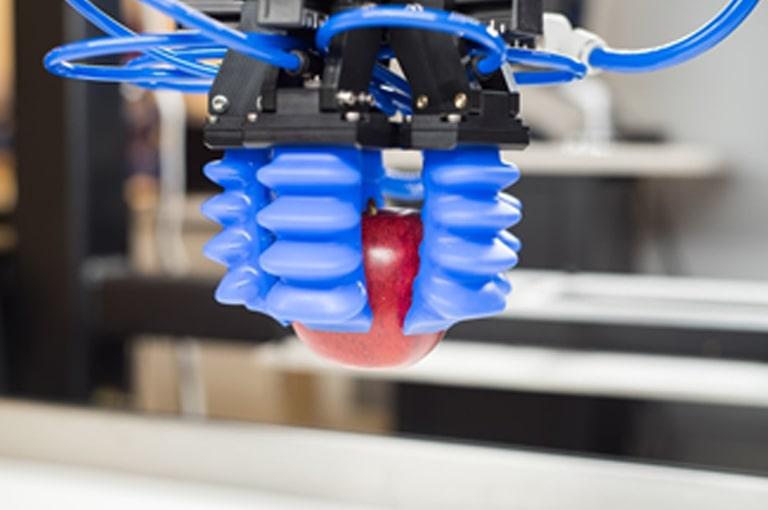

Robot tools

Design and build custom tools

Easy installation of tools

Use of abrasion resistant materials

Flexible fixtures

Tested designs

Robotic cells are pre-engineered or fully customized

For any application

For any industry

Independent of robot selection

Engineering solutions:

Controls, optimization, motion planning, machine vision:

Planning and implementation experience:

Design, control, movement planning of industrial robots: