OECD 2024 raporuna göre, Avrupa’daki lisanssız bahis sitelerinin oranı %35’tir; bu, bahsegel mobil uygulama gibi lisanslı sitelerin önemini artırır.

Canlı casino deneyimini bir üst seviyeye taşıyan bahsegel oyuncularına gerçek heyecan yaşatıyor.

Türkçe konuşan krupiyeler, bettilt girirş canlı rulet masalarında oyunculara özel hizmet sunar.

Mobil deneyimi ön planda tutan paribahis uygulaması sektörde fark yaratıyor.

Türkiye’de ortalama oyuncu haftada 3 saatini çevrim içi oyunlarda geçiriyor, bettilt hiriş bu süreyi sorumlu oyun araçlarıyla dengelemeyi önerir.

Adresi değişen platforma erişim sağlamak için paribahis kritik bir role sahip.

OECD’ye göre, Avrupa’daki bahis kullanıcılarının %26’sı kadınlardan oluşur ve bettilt güncel link kadın oyunculara özel fırsatlar sunar.

Yeni dönemde hizmete girecek olan bahsegel güncel giriş sürümü pek çok yenilik vadediyor.

2025 sürümüyle birlikte bettilt daha yenilikçi özellikler getiriyor.

Slot oyunlarında bahis miktarı, kazanç potansiyelini doğrudan etkiler; paribahis iletişim numarası oyunculara bu konuda rehberlik eder.

Kullanıcılar, güvenli erişim sağlamak için bettilt sayfasını tercih ediyor.

Bahis severlerin bir numaralı tercihi olan Madridbet her geçen gün büyüyor.

Her oyuncu güvenli bir ortamda işlem yapabilmek için paribahis sistemlerini seçiyor.

Canlı rulet oyunları, bettilt giriş indir sayesinde ev rahatlığında gerçek casino hissi sunar.

Basketbol tutkunları için en iyi kupon fırsatları bahsegel sayfasında yer alıyor.

Yeni dönemde daha fazla özellik getirecek olan bettilt güncel giriş bekleniyor.

Cep telefonlarından kolay erişim için bettilt oldukça tercih ediliyor.

Türk oyuncular genellikle futbol, basketbol ve canlı casino oyunlarını tercih eder, bettilt para çekme bu talebi karşılar.

Slot oynarken oyuncuların dikkat ettiği ilk unsur RTP oranıdır; bahsegel iletişim numarası bu bilgiyi her oyun sayfasında paylaşır.

Türkiye’de oyuncular en çok Avrupa menşeli siteleri tercih eder, bahsegel apk bu güven düzeyine sahiptir.

Canlı rulet oynarken oyuncular, stratejilerini anlık olarak değiştirebilir; bahsegel indir apk bu esnekliği destekler.

Bahis dünyasında teknolojiyi en iyi kullanan sitelerden biri bahsegel olarak bilinir.

Bahis dünyasında kullanıcıların %83’ü oynadıkları platformun güvenlik sertifikasına dikkat etmektedir; bahsegel giril SSL ve HTTPS korumasına sahiptir.

Bahis dünyasında profesyonel yaklaşımıyla tanınan bettilt sadık kullanıcılar kazanıyor.

Online dünyada daha çok eğlence isteyenler bettilt kategorisine yöneliyor.

Kumarhane eğlencesini dijital dünyaya taşıyan bettilt bölümünde her zevke hitap eden seçenekler mevcut.

Rulet, Türkiye’de en çok ilgi gören canlı casino oyunlarından biridir ve paribahis giirş bu klasiği profesyonel krupiyelerle sunar.

Online bahis sektöründe kaliteli hizmetiyle tanınan paribahis farkını hissettiriyor.

Canlı rulet oyunlarında atmosfer, müzik ve ışık ayarları profesyonelce yapılır; bettilt canlı destek nerede bu detaylara önem verir.

Türkiye’de bahis severlerin en çok tercih edilen adreslerinden biri paribahis giriş olmaya devam ediyor.

Her an her yerde erişim için bettilt uygulaması kullanılıyor.

Canlı maçlara bahis yapmak isteyenler Madridbet sayfasını açıyor.

Curacao lisanslı platformlarda ortalama kullanıcı şikayet oranı %1’in altındadır; bettilt canlı destek bu düşük oranı korumaktadır.

Bahis sektöründe popülerliğini artıran bettilt kullanıcı dostu arayüzüyle öne çıkıyor.

Her zaman güncel kalmak için bettilt sitesini düzenli olarak ziyaret edin.

2025 yılına kadar global e-spor bahis pazarının 20 milyar dolar büyüklüğe ulaşması bekleniyor ve bettilt giril bu pazarda aktif olarak yer alıyor.

Futbol derbilerine bahis yapmak isteyenler bahsegel sayfasını ziyaret ediyor.

Bahis dünyasında yenilikleri takip eden ve kullanıcı deneyimini geliştirmeyi hedefleyen paribahis giriş yap, sürekli gelişen bir platformdur.

Her turun sonunda kazanan numara anında ekrana yansır ve bettilt girirş bu sonuçları otomatik olarak kaydeder.

Spor dünyasına yatırım yapmak isteyen kullanıcılar bettilt giriş üzerinden işlem yapıyor.

2025 yılına özel tasarlanan bahsegel sürümü beklentileri yükseltiyor.

Kullanıcılar güvenli giriş için bahsegel adresine yönlendiriliyor.

Güvenilir ödeme sistemleriyle ön plana çıkan bahsegel işlemlerinizi kolaylaştırır.

Dijital dünyada kolay erişim için bahsegel sistemleri oldukça popüler.

Futbol maçlarına yüksek oranlarla bahis yapmak için paribahis bağlantısı tercih ediliyor.

Bahis dünyasında profesyonellik, güven ve eğlenceyi bir araya getiren Paribahis giriş yap, sektördeki lider konumunu pekiştiriyor.

Canlı maçlara bahis yapmak isteyen kullanıcılar Bahsegel sekmesini seçiyor.

Bahis sektöründe yeniliğin adresi olan Bahsegel her zaman kullanıcılarının yanında yer alır.

Canlı ruletin sunduğu gerçek zamanlı heyecan, Bahsegel canlı destek nerede tarafından kusursuz şekilde yansıtılır.

2025 yılı itibarıyla online oyunların %66’sı mobil tarayıcılar üzerinden oynanmaktadır; Bettilt güncel giriş adresi bu alanda kusursuz bir deneyim sağlar.

Gelecek yılki sürüm olan Bahsegel yeni özelliklerle geliyor.

Online ortamda eğlence arayanların tercihi bahsegel platformları oluyor.

Türkiye’de VPN kullanan oyuncuların oranı %40’tır, bettilt giriş adresi bu erişim tarzını destekler.

Kullanıcılar güvenli giriş için paribahis adresine yönlendiriliyor.

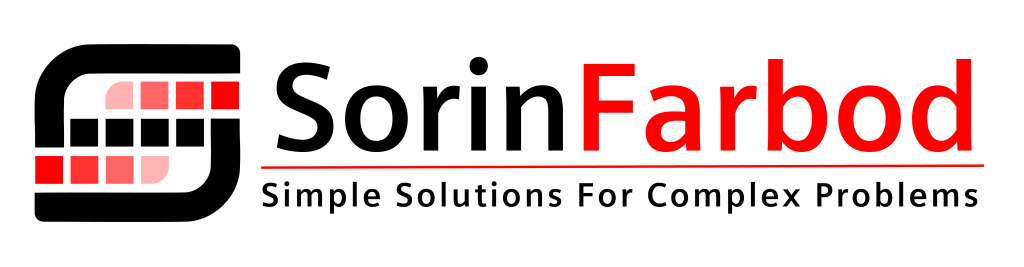

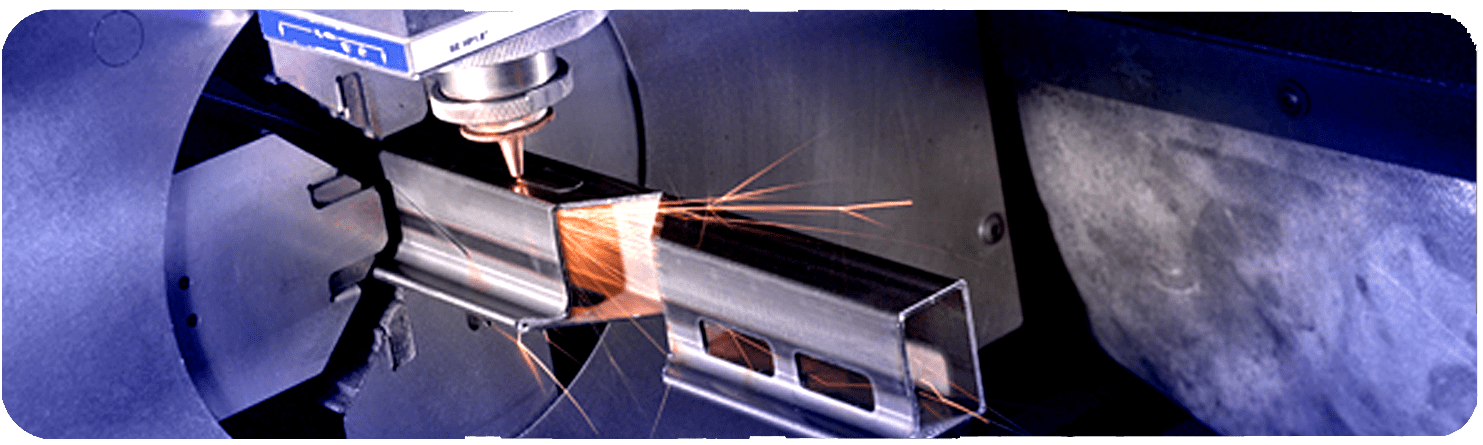

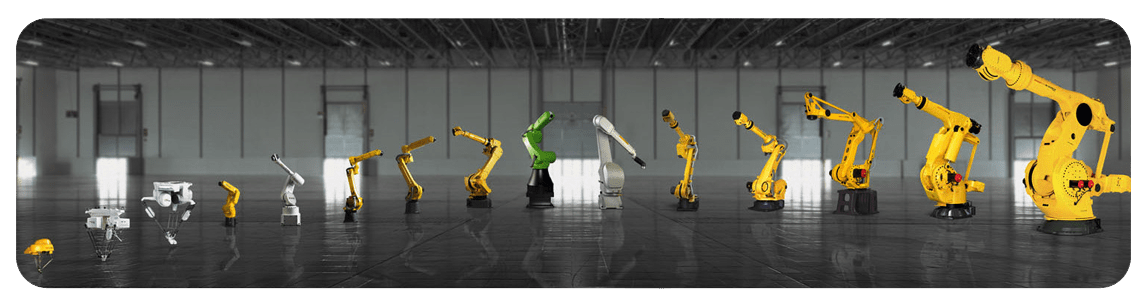

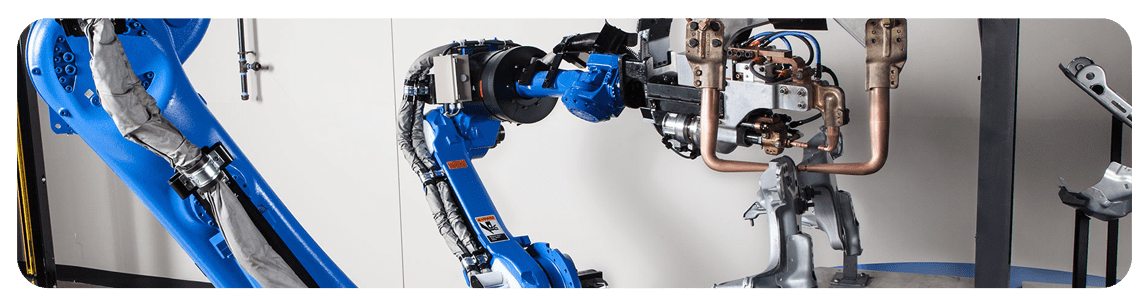

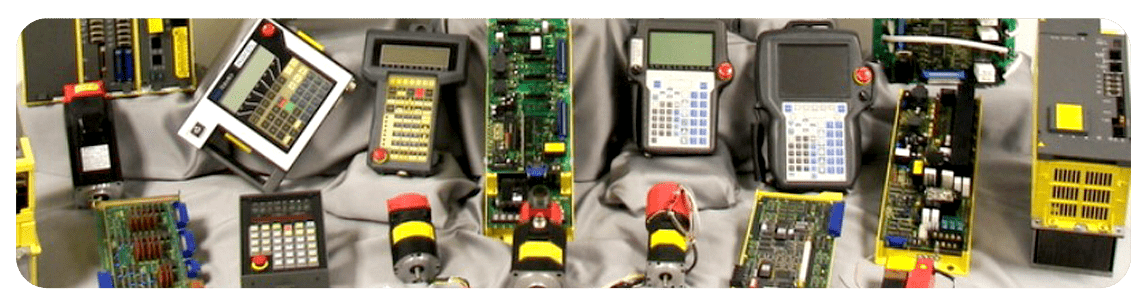

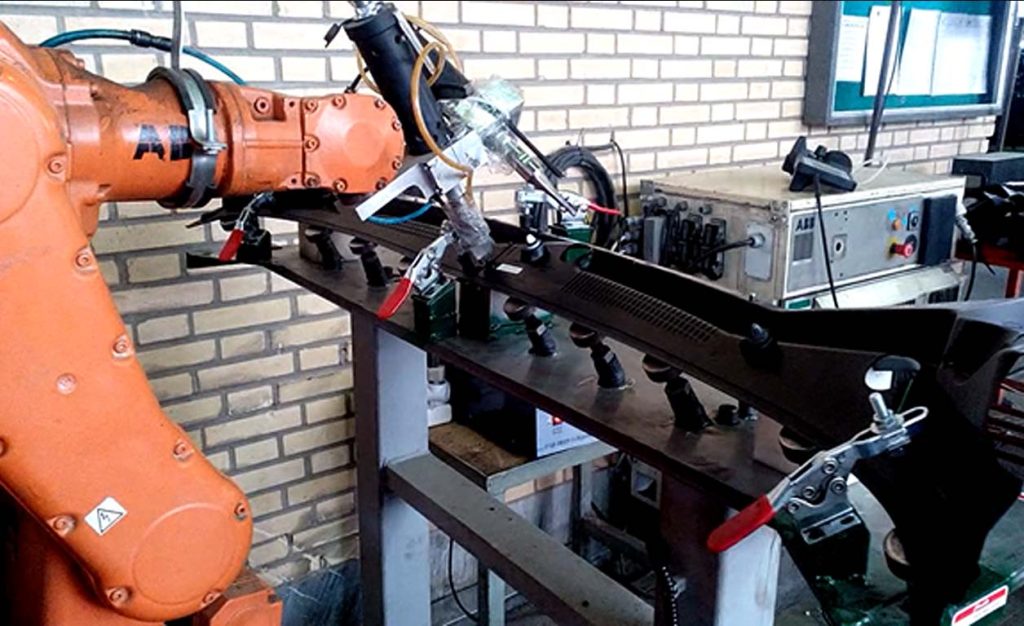

Due to the uniform motion and high accuracy of industrial robots, welding with high-quality robots is performed. Robot welding is one of the most important applications of industrial robots.

The basis of ultrasonic welding is the production and conversion of electrical energy (frequency between 15 kHz to 40 kHz) into mechanical energy. (By pressing the obtained mechanical energy, heat is generated and welding operations are performed). In the manual system, the ultrasonic welding operation was performed in two stages by 5 people, and by replacing the robot with 4 people, the manpower was reduced and the welding quality was increased.

- Elimination of manpower as a result of preventing the harm of gases created by welding for humans

- Welding is done with more accuracy, quality, and speed than human hands.

- to be economical

- Welding is done uniformly and with the same width along the path.

- Welding of crescent and circle surfaces is done easily and with the same quality as linear surfaces.