Online oyun lisansına sahip sitelerin %55’i Avrupa merkezlidir ve Bahsegel giril bu bölgedeki düzenlemelere tam uyumludur.

Klasik kumarhane heyecanını evinize getiren Bettilt platformda bolca mevcut.

İnternet üzerinden keyifli vakit geçirmek için Bettilt giris bölümü kullanılıyor.

2024 yılında dünya genelinde 5 milyardan fazla bahis kuponu oluşturulmuştur; bu rakamın önemli bir kısmı paribahis güncel link kullanıcılarına aittir.

Mobil uyumlu tasarımı sayesinde her yerden erişim imkanı sunan paribahis her zaman yanınızda.

Kullanıcıların sorunsuz giriş yapabilmesi için bahsegel adresi güncel tutuluyor.

İnternette eğlenceyi sevenler için bahsegel güncel adres sistemleri cazip fırsatlar sunuyor.

Avrupa’da online casino kullanıcılarının %50’sinden fazlası haftada en az bir kez oyun oynuyor; bahsegel guncel giris bu eğilimi destekleyen promosyonlar sunuyor.

Bahis dünyasında kazanç arayanlar için paribahis kategorileri geniş seçenekler sunuyor.

Bahis sitelerinde canlı krupiyeli oyun oynayan kullanıcılar, RNG oyun oynayanlara göre %25 daha yüksek sadakat oranına sahiptir; bu oran paribahis girş’te daha da yüksektir.

Türkiye’de bahis severlerin en çok tercih edilen adreslerinden biri casino giriş olmaya devam ediyor.

Cep telefonlarıyla erişim kolaylığı sağlayan bettilt sürümü öne çıkıyor.

Türkiye’deki bahisçilerin güvenini kazanan bettilt güvenilir yapısıyla öne çıkıyor.

Kullanıcı deneyimini öncelik haline getiren bahsegel tasarımıyla öne çıkıyor.

Rulet, poker ve slot makineleri gibi seçeneklerle dolu bettilt giriş bölümü farklı deneyimler yaşatıyor.

Statista verilerine göre 2024 yılında online slot oyunlarının toplam oyun gelirlerindeki payı %60’ı aşmıştır; bettilt canlı destek slot kategorisinde 1800’den fazla oyun sunmaktadır.

Kazancını artırmak isteyenler için Paribahis promosyonları cazip hale geliyor.

FEATURE

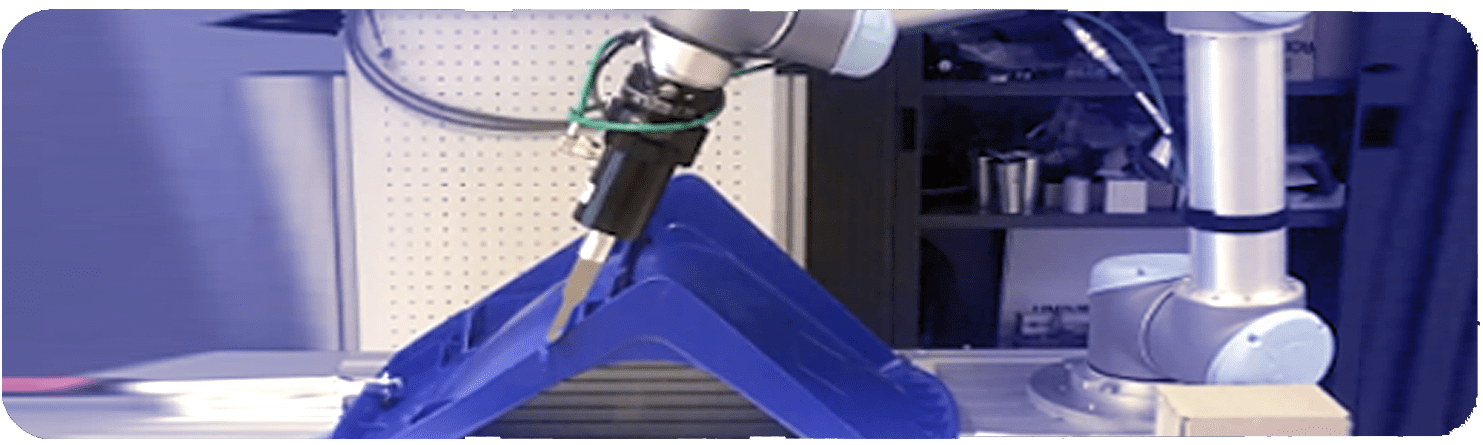

This platform two-axis servo positioner mainly consists of the welding base, the rotary frame, the

AC servo motor, the RV precise reducer, the rotary support , the conductive system, the protective

cover and the electrical control system.

The whole welding frame is made by high-quality sections. The machining was after stress relief

annealing, which ensured the machining accuracy and the use accuracy. Anti-rust appearance

paint is beautiful and elegant, and the color can be customized.

Rotary frame is made by high-quality steel section with professional machining. With standard pith

tapped hole on the surface for installing positioning tooling, it was painted after black oxidation

treatment.

The AC servo motor matching the RV reducer can guarantee high rotary stability, high positioning

accuracy, long durability and low failure rate.

The conductive mechanism is made in brass, which give perfect conduction. The foundation is whole insulation to protect the servo motor, robot, welding power, etc.

We choose Omron(Japan) PLC to control the positioner and electrical elements are all from famous

brands, which ensures the high stability and the low failure rate.

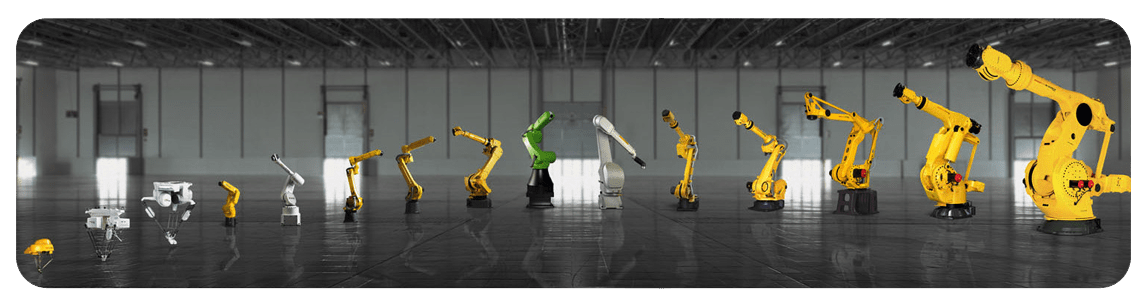

CHARACTER

* Support Chinese/English/Japanese/Polish Spanish

* Programmable robot body , cables are made of special cables for flexible robots

* Support domestic and imported reducer mix, pure import, servo and reducer all import

* Support Chinese configurations or adopts imported reducer configurations of

NABTESCO, SHIMPO, etc

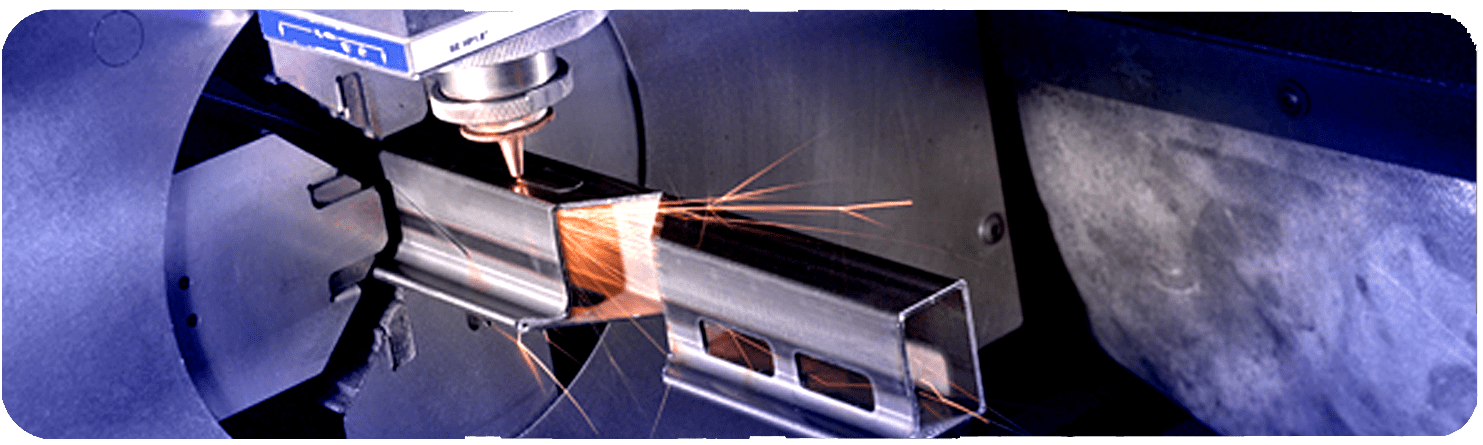

FEATURES

※With large working space and fast running speed, our industrial robots are ideal for welding, spraying, machine tool loading and unloading, handling, sorting, assembling

and other applications.

※Use Italian design technology in mechanical and circuit, and take in ABB wiring layout technology in our robot body manufacturing. Modular design to simplified wiring, double safety circuit design, dust protection design for electricity cabinet.

※Support single phase, 220V working voltage can be better adapted in various

environments. The robot body is with dual-circuit gas pipe and meets the welding and

handling requirements.

※Programmable robot body, cables are made of special cables for flexible robots.

※6+3 Axis (Standard 6 Axis, External 3 Axis is Optional).

※Support external PLC, arc tracking and other accessories (optional), visual software

(optional), laser tracking software (optional), arc tracking software (optional), etc.

※Support Chinese/English/Japanese/Polish Spanish.

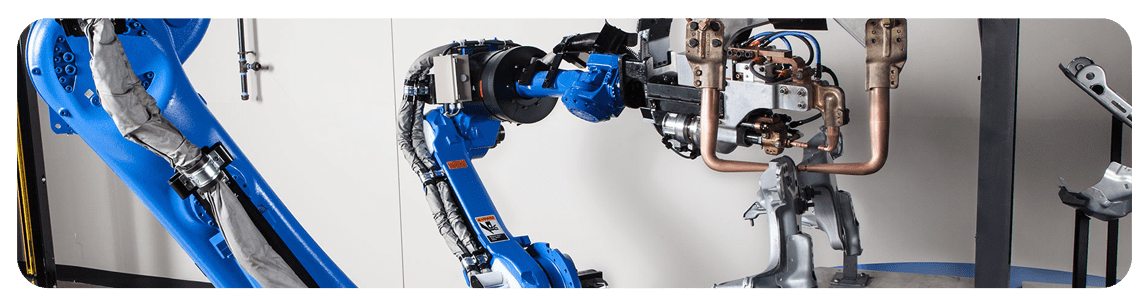

ROBOTIC ARM PROCEDURE

※ Bending: can realize constant speed tracking, real-time sensor tracking, bending

following and automatic return to equality function.

※ Spaying: four analog interfaces are provided, and standard trajectory template is built in to generate spray trajectory quickly. At the same time, it supports users to build their

own spraying trajectory.

※ Palletizing: by setting the basic parameters of the size, number and number of layers of palletizing, the palletizing and disassembling functions can be realized by simple palletizing instructions.

※ Tracing: when the object moves on the conveyor belt, it can realize single tracking

(grabbing, spraying, etc.) or multiple tracking (assembling, etc.) of the product. It can set

tracking detection point, start point, end point and detection range arbitrarily.

※ Press tending: for press punching industry, a set of solutions for punching process, punching interface and punching connection are developed, which are convenient for customers to connect quickly, use simply and adjust the rhythm.

※ Pick and place.

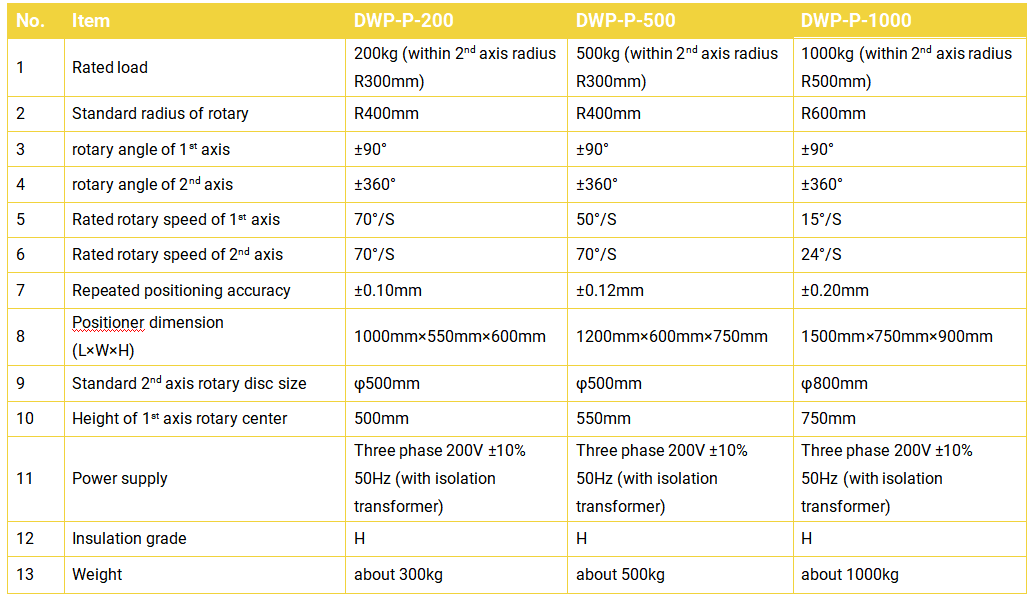

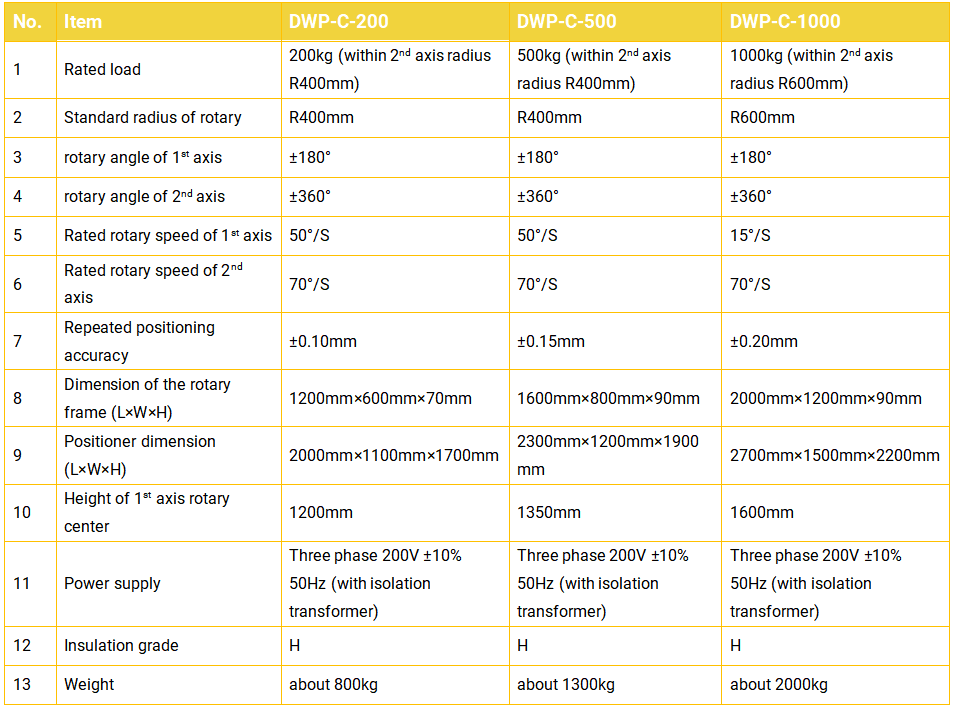

TECHNICAL SPECIFICATION

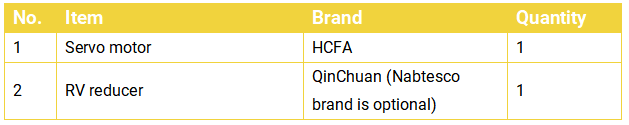

CONFIGURATION LIST:

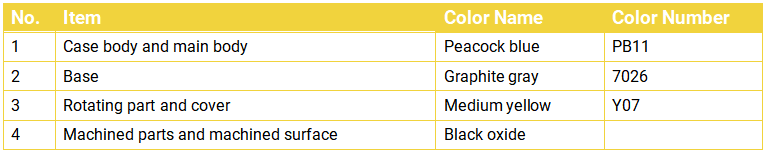

STANDARD COLOUR OF THE EQUIPMENT

TECHNICAL SPECIFICATION